The production of human milk oligosaccharides (HMOs) typically involves complex biological fermentation processes, which require specialized fermentation equipment and techniques.

Although the specific equipment model details regarding the fermentation of oligosaccharides in breast milk may be updated frequently with market and technological developments, some relevant information and trends can be shared:

2. Technological innovation: With the deepening of research on HMO and technological progress, more and more companies may adopt advanced biotechnology, such as using specific engineering strains for efficient fermentation, as well as modern separation technologies such as membrane separation and chromatographic separation to optimize production processes.

3. Customized solutions: Given the particularity and high technological threshold of HMO production, there are suppliers in the market who provide customized fermentation equipment and services to meet the specific needs of different manufacturers for production capacity, automation level, and product quality.

4. Industry application: As a food additive, infant formula ingredient, and potential health supplement, HMOs production equipment also needs to comply with strict food safety and hygiene standards to ensure the safety of the final product.

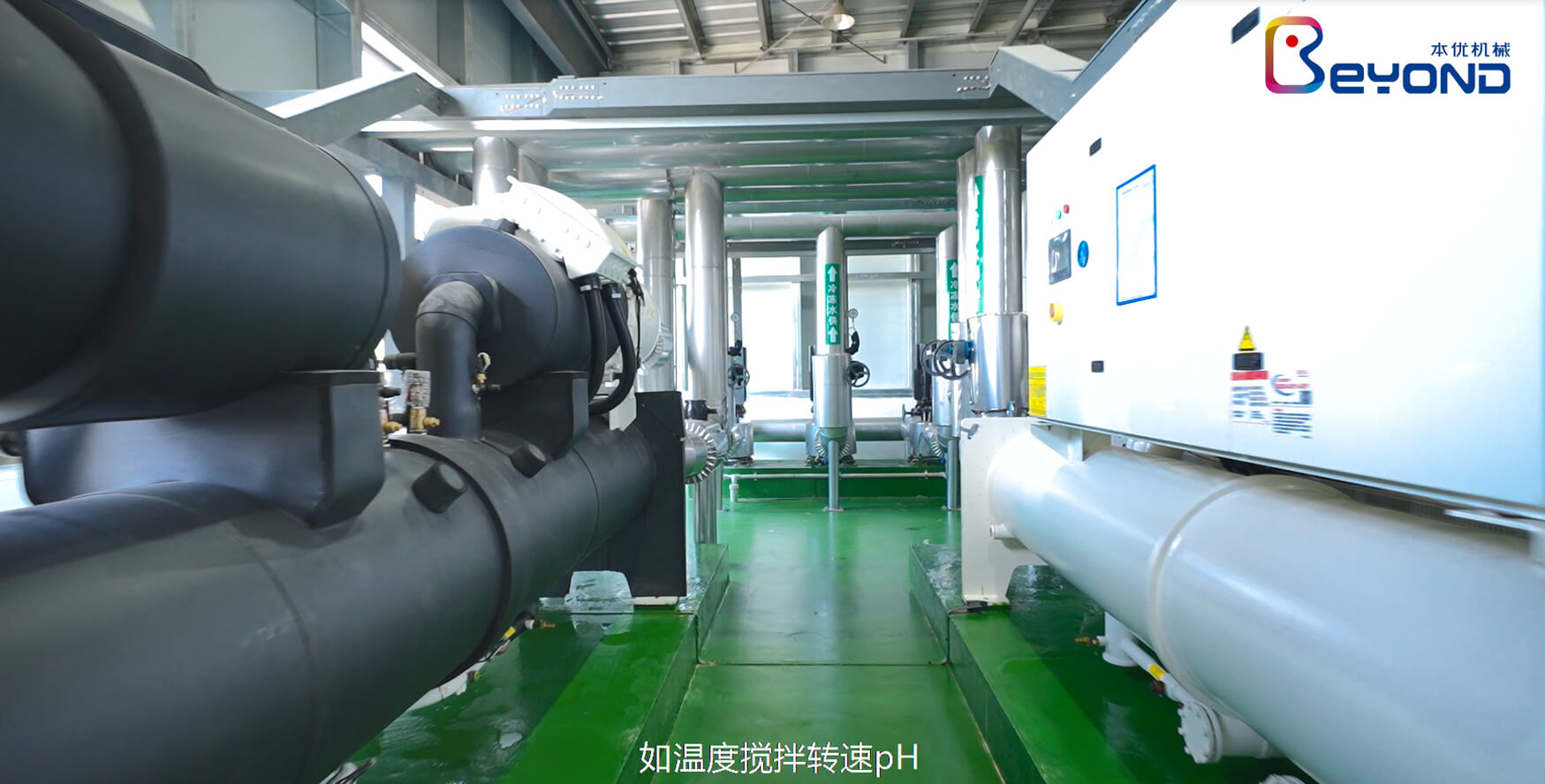

Installation and commissioning of milk oligosaccharide fermentation equipment

The installation and debugging of fermentation equipment for human milk oligosaccharides (HMOs) is a complex and professional process, which usually involves the following key steps, combined with the general principles of fermentation equipment installation and debugging and the special requirements of HMOs production process:

Preliminary preparation and inspection:

Confirm equipment specifications and on-site conditions: Based on the drawings and instructions provided by the equipment manufacturer, confirm the size, weight, installation position, and environmental requirements of the fermentation tank (such as sterile environment, temperature and humidity control, etc.).

Infrastructure preparation: Ensure that the ground is level, compacted, and necessary moisture-proof layers are laid. Prepare water and electrical interfaces that meet the requirements Basic construction and fixation: • Installation support structure: Install suitable brackets or bases according to the weight and usage requirements of the fermentation tank, and fix them with underground embedded bolts to ensure the stability and safety of the equipment Horizontal calibration: Ensure that the fermentation tank is in a horizontal state after installation, which is crucial for maintaining the stability of the fermentation process Equipment assembly and connection: • Component inspection and assembly: Check each component one by one for damage, and follow the instructions to assemble the fermentation tank and other auxiliary equipment (such as mixing system, temperature control system, gas supply system, etc.) Sealing test: After assembly, conduct a sealing test to ensure that there are no leaks at the tank and pipeline connections.

• Electrical and control system installation: • Electrical connection: Connect the power supply, sensors, and control panel correctly according to the electrical drawings, ensuring that all electrical equipment complies with safety regulations.

System debugging: Preliminary debugging of the control system, including the setting of PID controller (proportional integral differential controller), to ensure that parameters such as temperature, pH value, stirring rate can be adjusted as needed and feedback is accurate.

• Pipeline and ventilation system installation: • Pipeline connection: Complete the connection of inlet and outlet, steam, cooling water, air, and other pipelines, and conduct pressure testing to ensure no leakage.

Air purification system: If necessary, install and debug the air purification system to ensure a sterile fermentation environment.

• Safety and environmental measures: • Install safety devices such as emergency stop buttons, pressure relief valves, etc. to ensure production safety.

Environmental compliance: Ensure that wastewater and exhaust gas treatment facilities are installed in place and comply with local environmental standards.

• Trial operation and performance verification: • No load trial operation: Start the equipment for the first time for no-load testing, check whether all components are operating normally, and adjust control parameters to the optimal state.

Load testing: Gradually add the culture medium for small-scale fermentation experiments, monitor various indicators, and make fine adjustments based on the fermentation effect.

• Training and documentation: • Operation training: Provide training to operators on equipment use, maintenance, and safe operation.

Document organization: Record the installation and debugging process, prepare operation manuals and maintenance guidelines for future reference and adherence. The entire installation and debugging process should strictly follow the manufacturer's guidance and relevant industry standards, and if necessary, hire an experienced professional team to ensure that the equipment is efficiently and safely put into production.

Shanghai Beyond Machinery Co., Ltd.

Beyond Machinery specializes in the design and manufacturing of Breast milk oligosaccharide fermentation equipment. Please contact us now, and our professional technical engineers will customize the equipment plan for Breast milk oligosaccharide fermentation equipment and provide a quotation. Please contact us now to obtain the latest equipment plan and quotation.