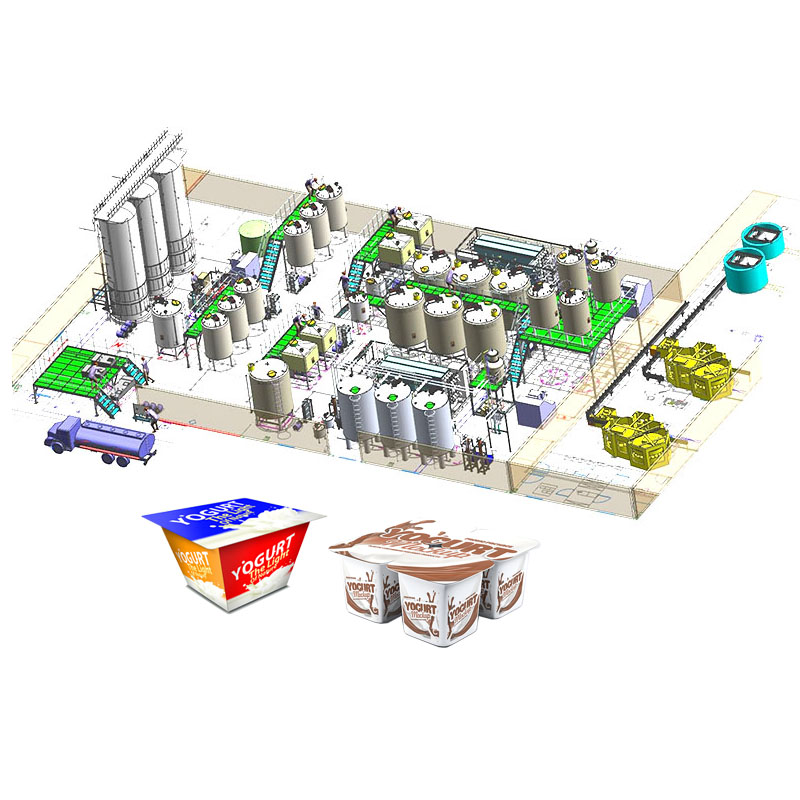

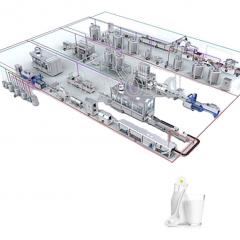

A yogurt processing line is a series of equipment and machinery used to produce yogurt in a large-scale production setting. The line typically includes various stages and processes, such as milk reception, milk storage, pasteurization, homogenization, fermentation, cooling, flavoring, filling, packaging, and labeling.

Milk Reception: Raw milk is received and tested for quality before it is stored in designated tanks.

Milk Storage: Milk is stored in temperature-controlled tanks to maintain its freshness and quality.

Pasteurization: The milk is heated to specific temperatures to kill harmful bacteria while preserving beneficial enzymes and nutrients.

Homogenization: The milk is then homogenized to ensure a consistent texture and prevent separation of cream.

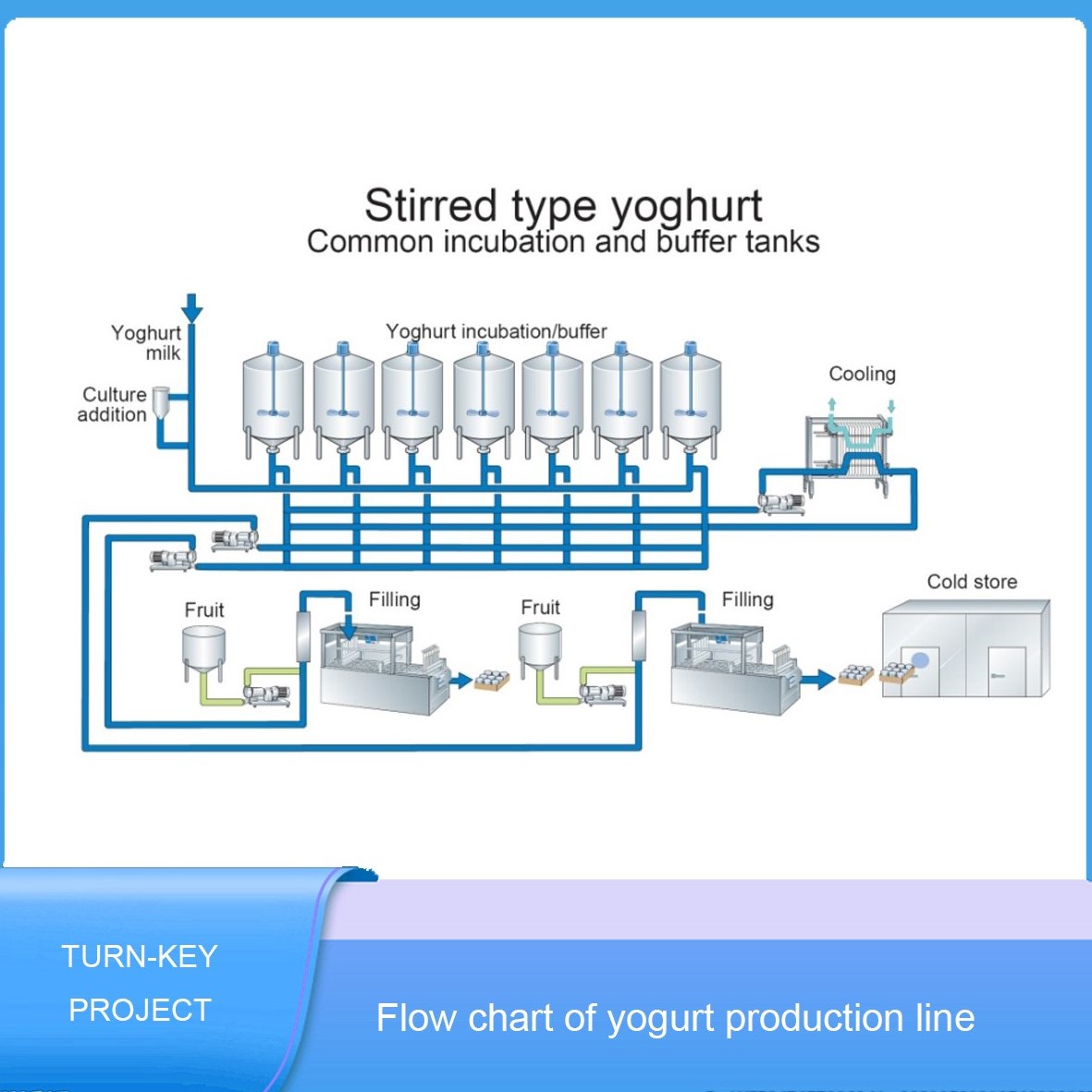

Fermentation: The milk is inoculated with live cultures of bacteria (such as Lactobacillus bulgaricus and Streptococcus thermophilus) and incubated at controlled temperatures to allow the fermentation process to occur.

Cooling: Once the desired fermentation time is reached, the yogurt is cooled to stop the fermentation process and stabilize the product.

Flavoring: Flavors, fruits, or other additives are added to the yogurt to enhance taste and texture.

Filling: The yogurt is filled into individual containers, such as cups or bottles, through automated filling machines.

Packaging: The filled containers are then sealed, either by heat-sealing or using lids, and prepared for further processing.

Labeling: The containers are labeled with product information, including nutritional facts, ingredients, and branding.

Quality Control: Throughout the process, quality control measures are implemented to ensure that the yogurt meets the desired standards for taste, texture, and safety.

Storage and Distribution: The packaged yogurt is stored in appropriate conditions before being distributed to retailers or consumers.

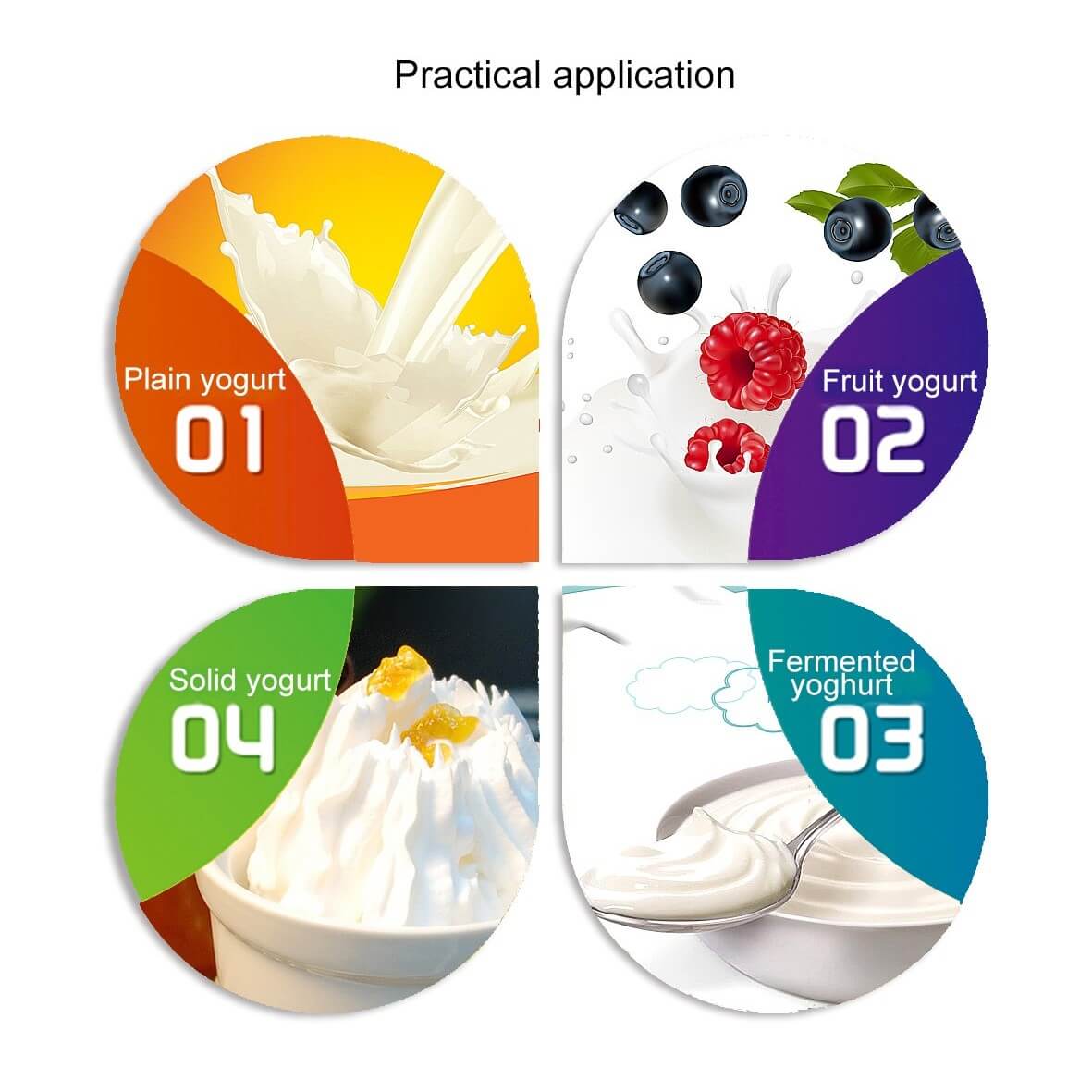

Types of yoghurt: setting type, stirring type and adding various fruit juice jam and other accessories fruit flavor yogurt.

Packing form: HDPE plastic bottle, plastic cup, plastic bag, roof bag, glass bottle

Output: 2T / D-500T / D

Main equipment system

Item

Data

Composition of yoghurt fermentation

system.

Yoghurt fermentation system

includes: online culture addition system, ultra-clean fermentation tanks

system, aseptic air system,flexible cooling system and matched pipes,

valves,instruments and control programs, etc.

online culture addition system

The online culture addition system

adopts the ultra-clean culture online addition method, which includes culture

adding tube that

ultra-clean fermentation tanks

system

The ultra-clean fermentation tanks

system mainly refers to the fermentation tanks and auxiliary configuration to

be used in the yoghurt fermentation process

Flexible cooling system

The flexible cooling system mainly

includes a large channel low flow rate plate and a constant temperature water

system. Through this system, the fermented yoghurt can be cooled to about 20℃,and the

cooling temperature difference less than 5℃dT, which

can

Aseptic air system

Aseptic air system includes SUS304

bracket, including degreasing and dewatering filter, activated carbon filter,

coarse filter,sterilizing filter, steam filter; compressed air pressure

reducing valve, steam pressure reducing valve, pressure gauge,temperature

probes, etc., this system can be steam sterilized and CIP cleaned.It is used

for the protection of micro positive pressure in the tank during the fermentation

process, which can prevent the materials in the tank from being contaminated

can fit different types of cultures and an aseptic filter air positive

pressure protective cover that reaches a 100-level purification level

minimize the damage of the yoghurt viscosity, which can achieve better

post-fermentation effect.

by the outside enviroment.

Equipment list sample of complete yogurt processing line

|

Equipment list of complete yogurt processing line (pasteurized milk/yogurt/cheese/cream/butter) |

|

| Name | Main technology parameter |

| Milk receive, storage and cream separator unit | |

| Electron pound scale | Maximum weighing 500KG |

| Milk weighing tank | SUS304, single layer, product feeded in through 40 mesh filter net, CIP cleaning ball |

| Milk acceptor | SUS304, single layer, CIP cleaning ball |

| Milk pump | SUS304, pump lift 24m, hard alloy mechanical seal, inner shell mirror polished |

| Twin piping filter | SUS304, two pipe, stainless steal filter element 100 mesh |

| Dish separator | Auto residue discharge |

| Chiling tank | SUS304, alveolate jacket, attached with compressor |

| Milk pump | SUS304, pump lift 24m, hard alloy mechanical seal, inner shell mirror polished |

| Preparing unit | |

| Blending tank | SUS304, heat insulated, top off center vertical agitator, conical head, airtight manhole, breather valve, digital readout thermometer, anti-eddy baffle, supporters with adjustable feet |

| Milk pump | SUS304, pump lift 24m, hard alloy mechanical seal, inner shell mirror polished |

| Mini set of plate-type heat exchanger | SUS304, two stages |

| High speed emulsification tank | SUS304, heat insulated, bottom high speed emulsifier, digital readout thermometer,s upporters with adjustable feet |

| Milk pump | SUS304, pump lift 24m, hard alloy mechanical seal, inner shell mirror polished |

| Twin piping filter | SUS304, two pipe, stainless steal filter element 100 mesh |

| Sterilizing and homogenizing unit | |

| UHT sterilizer | Tub-type, sterilzing temperature 137 C, holding time 4s, full automatic control |

| High pressure homogenizer | 40MPa (starting box included) |

| Temperature holding | SUS304, holding 300s |

| Distributing plate | SUS304, 3 holes |

| Cheese/butter processing unit | |

| Bufferying tank | SUS304, heat insulated, top off center vertical agitator, conical head, airtight manhole, breather valve, digital readout thermometer, anti-eddy baffle, supporters with adjustable feet |

| Milk pump | SUS304, pump lift 24m, hard alloy mechanical seal, inner shell mirror polished |

| Cream seperator | |

| Bufferying container | SUS304, with cover |

| Milk pump | SUS304, pump lift 24m, hard alloy mechanical seal, inner shell mirror polished |

| Butter churner | SUS304, stepless timing |

| Cheese vat | SUS304, with heating jacket and insising device |

| Pressor | SUS304, 6 heads |

| Mould | SUS304, 10L, with cover |

| Yogurt fermentation unit | |

| Fermentation tank | SUS304, heat insulated, top off center vertical agitator, conical head, airtight manhole, breather valve, digital readout thermometer, anti-eddy baffle, supporters with adjustable feet |

| Rotary pump | SUS304, hard alloy mechanical seal, manual stepless shift |

| Plate cooler | SUS304, single stage, milk discharge at 4C |

| Rotary pump | SUS304, hard alloy mechanical seal, manual stepless shift |

| Filling unit | |

| Higher position tank | SUS304, heat insulated, top off center vertical agitator, conical head, airtight manhole, breather valve, digital readout thermometer, anti-eddy baffle, supporters with adjustable feet |

| Pasteurized milk filling machine | |

| Yogurt filling machine | |

| CIP system unit | |

| Semi-auto CIP system | Outer shell of SUS304, inner shell of SUS316, single cleaning way, concentrated acid/alkali tank adding system based on US technology, 100L×2 acid/alkali concentrate tanks |

| CIP return pump | SUS304, pump lift 24m, hard alloy mechanical seal, inner shell mirror polished |

| Installation part |

Whole milk processing line installation and commissioning |

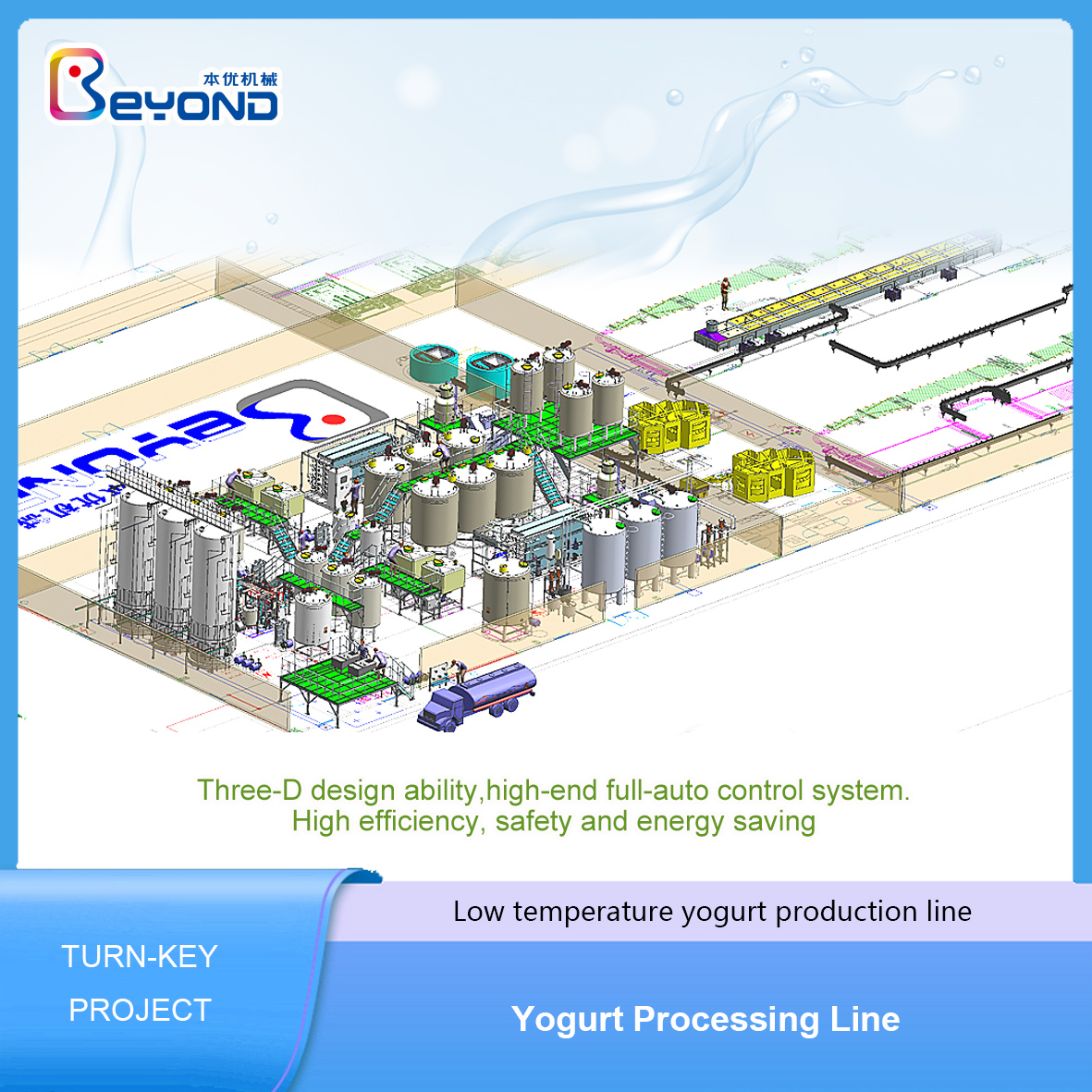

The yogurt processing line can be customized according to customer needs, so that the performance of the yogurt processing line can fully meet the production needs of customers, minimize customer investment and improve customer production efficiency. Our professional engineers are responsible for the design, manufacture, installation and commissioning of the yogurt processing line, making the customer's equipment investment very safe and reliable. Our yogurt processing lines have customers in many countries around the world who have achieved their own success in different industries.

Service process

Note that the specific equipment and processes involved may vary depending on the scale of production, the desired yogurt type (such as Greek yogurt or flavored yogurt), and other factors.