The powder tower in the milk powder processing line usually refers to the key equipment used in the milk powder production process - spray drying tower, also known as the powder spray tower. This equipment is mainly used to quickly dry liquid or slurry raw materials (such as fresh milk, concentrated milk, etc.) into powdered milk powder through specific spray technology.

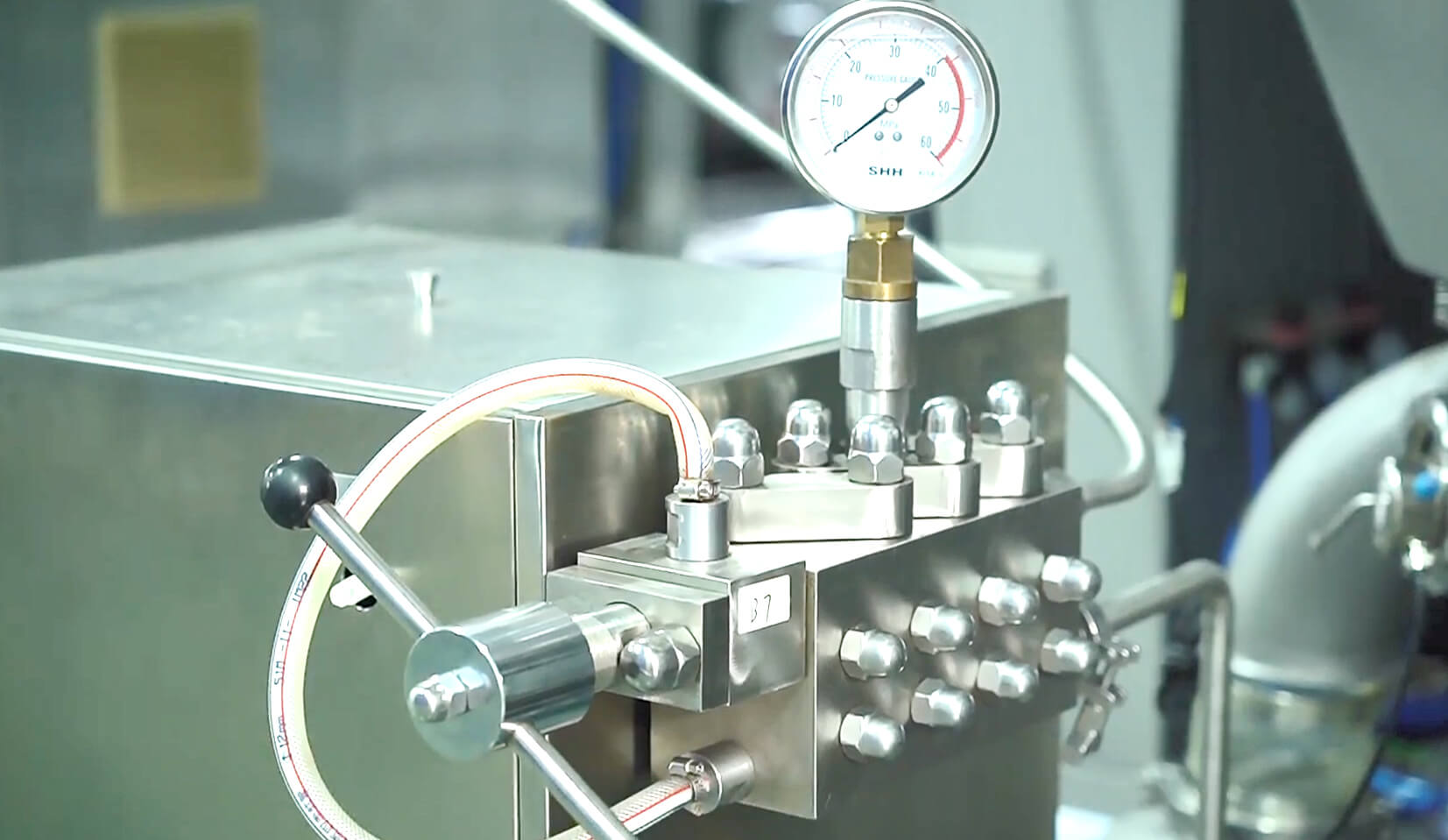

1. Atomization: The raw milk enters the spray drying tower after pretreatment (such as pasteurization, standardization, homogenization, etc.). In the tower, the raw milk is atomized into small droplets through a centrifugal spray or a high-pressure nozzle. The purpose of atomization is to increase the surface area, allowing the liquid to come into full contact with hot air in a short period of time, thereby achieving efficient drying.

2. Drying: the atomized lotion drops contact with the hot air in the tower countercurrent. Hot air can be generated by direct or indirect heating, and the temperature is usually controlled within an appropriate range to ensure the quality and safety of milk powder. The water in the droplets evaporates rapidly and turns into water vapor. At the same time, the lotion droplets solidify into tiny milk powder particles.

3. Separation and cooling: The dried milk powder particles rise together with hot air and undergo gas-solid separation through built-in cyclone separators and bag filters. These devices can effectively capture milk powder particles and discharge exhaust gas. The separated milk powder particles have a higher temperature and usually need to be further cooled by a cooling system to a suitable storage temperature.

4. Collection and packaging: The cooled milk powder particles enter the collection system through the discharge port, such as a vibrating screen or fluidized bed, for particle size screening and uniform mixing, removing possible clumps and ensuring product quality consistency. Finally, qualified milk powder particles are sent to the packaging process and packaged into various specifications of milk powder products that consumers can see.

• Centrifugal spray or high-pressure nozzle: ensure that the raw milk is atomized into even and small enough droplets to achieve good drying effect and the fineness of the final milk powder particles.

Hot air system: including air filtration, heater, hot air distributor, etc., providing stable and temperature controlled hot air to ensure drying efficiency and milk powder quality.

Tower body and internal structure: Designing a reasonable tower diameter, height, and internal components (such as guide tubes, cyclone separators, bag filters, etc.) can help optimize airflow distribution, improve drying efficiency, and product yield.

Air hammer and vibration device: installed on the tower wall and separator, regularly vibrated to prevent the adhesion of milk powder particles, maintain cleanliness inside the tower, and reduce product loss.

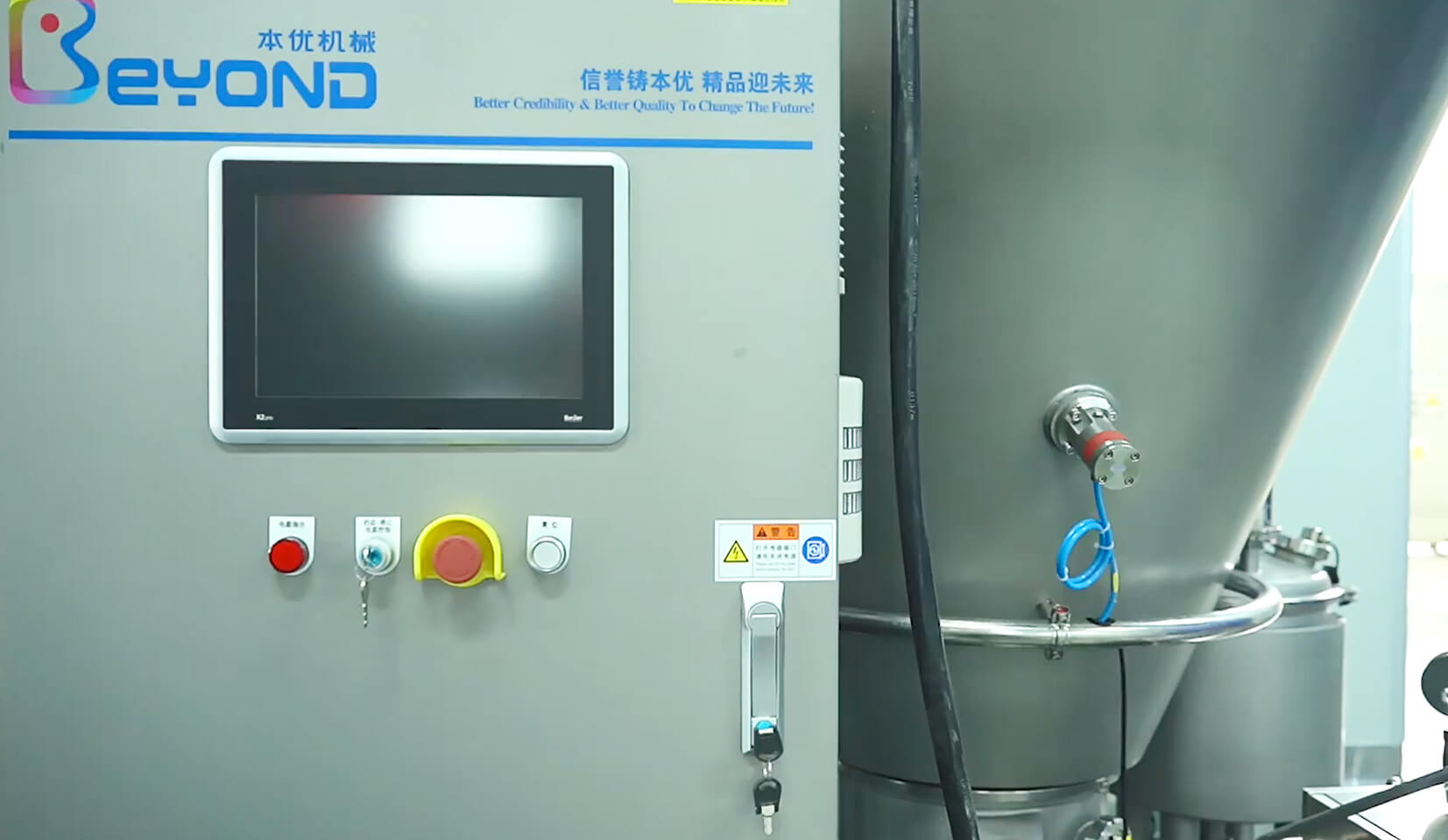

Control system: including monitoring and automatic adjustment of parameters such as temperature, humidity, wind speed, liquid material flow rate, etc., to ensure precise control of the entire drying process and stability of product quality.

Energy saving and environmental protection measures: The powder spray tower in modern milk powder processing lines usually adopts the following energy-saving and environmental protection technologies:

• Waste heat recovery: Utilizing the heat generated from the large amount of wet and hot exhaust gas during the drying process, the fresh air entering the tower is preheated through a heat exchanger to reduce energy consumption.

Energy management system: integrates advanced energy monitoring and optimization algorithms, adjusts operating parameters in real-time, and maximizes energy utilization efficiency.

Dust emission control: equipped with efficient exhaust gas purification devices to ensure compliance with strict environmental standards and reduce the impact on the atmospheric environment.

To sum up, the powder tower (spray drying tower) in the milk powder processing line, as the core equipment, integrates many process steps such as atomization, drying, separation and cooling. Through precision design and advanced control technology, it realizes the efficient, safe and energy saving transformation from liquid dairy products to high-quality milk powder.

Shanghai Beyond Machinery Co., Ltd

Beyond Machinery specializes in the design and manufacturing of Milk Powder Production Lines. Please contact us now, and our professional technical engineers will customize the equipment plan for Milk Powder Production Lines and provide a quotation. Please contact us now to obtain the latest equipment plan and quotation.