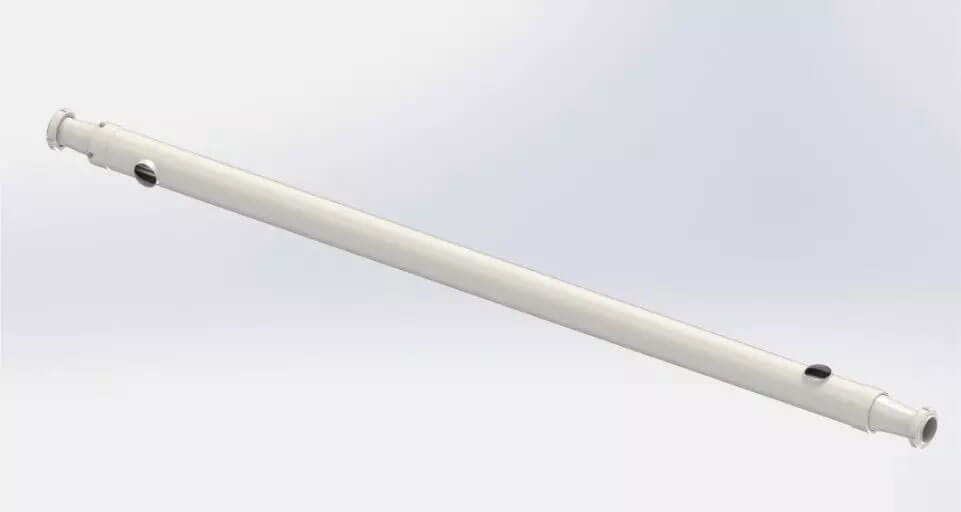

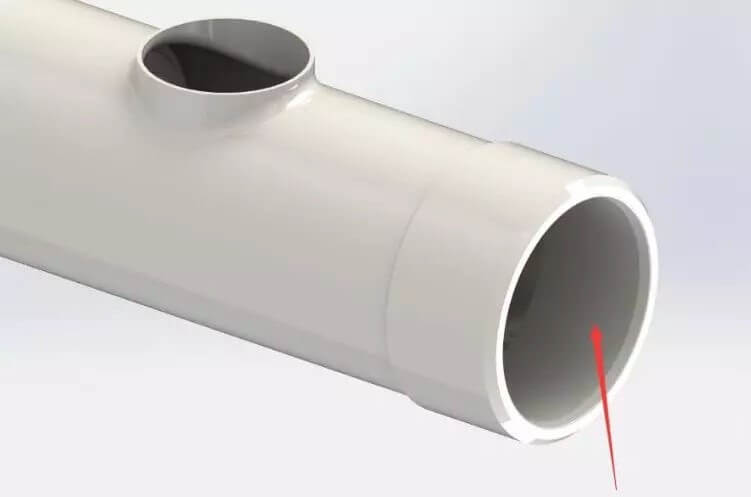

After long-term use of the tubular heat exchanger, the sealing performance of the O-ring will decline, and impurities may enter into the heat exchanger, which will affect the continuous normal use of the heat exchanger. Therefore, regular maintenance and repair of the heat exchanger is essential.

1, 1 hexagon wrench, 2, 1 set of special disassembly tools

3. One piece of grease, four pieces of dust-free paper

02 disassembly analysis

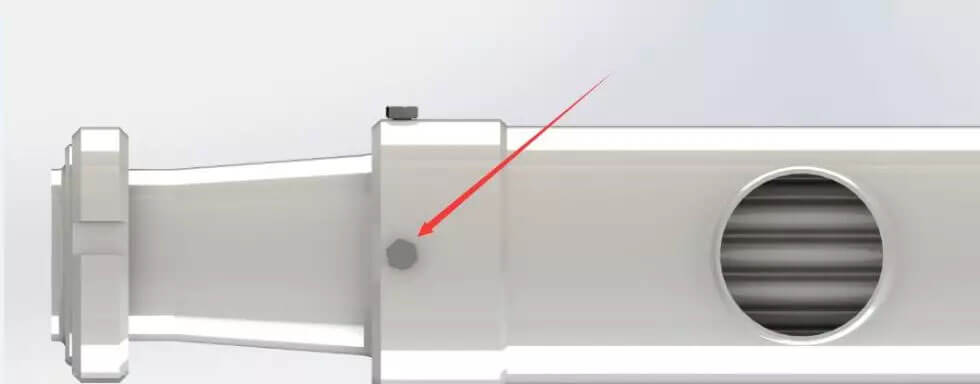

In order to ensure safety, the maintenance of the heat exchanger can be carried out only when it has been out of use and under normal temperature.1) Remove the locating bolt on one side of the heat exchanger with a hexagonal wrench;

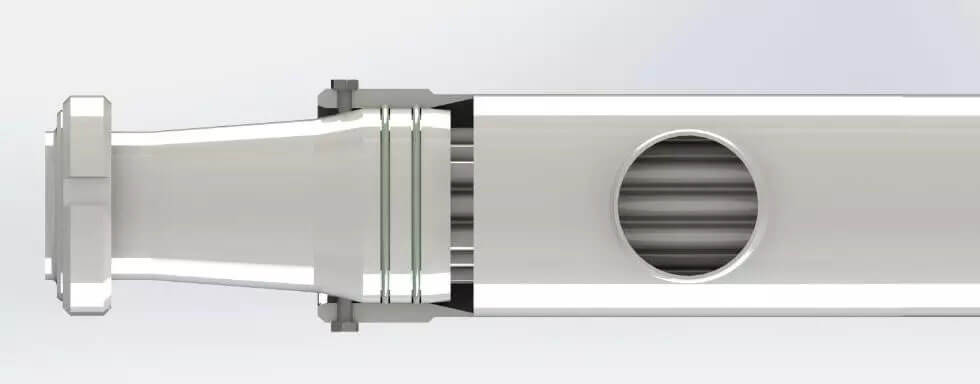

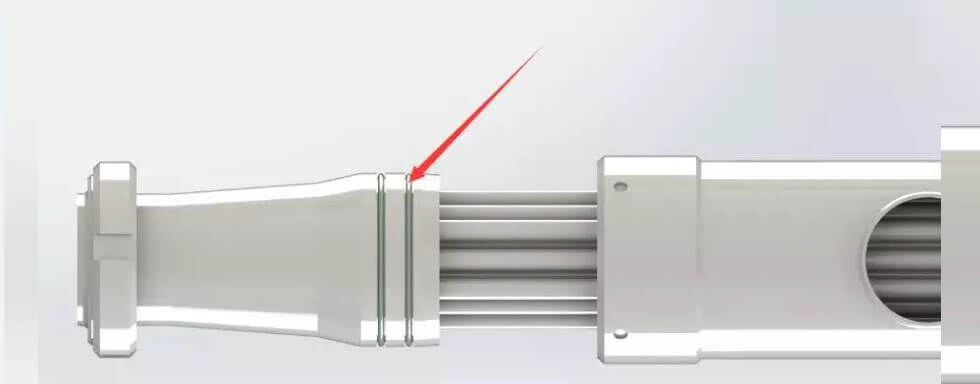

2) Push out the heat exchange tube from the opposite side, remove the O-ring with a special tool, clean and wipe the sealing groove with dust-free paper, and then apply lubricating grease evenly;

4) After steps 2 and 3 are completed on both sides, replace the O-ring with a new one;

5) Reset the heat exchanger and tighten the positioning bolts to complete the maintenance of the heat exchanger;