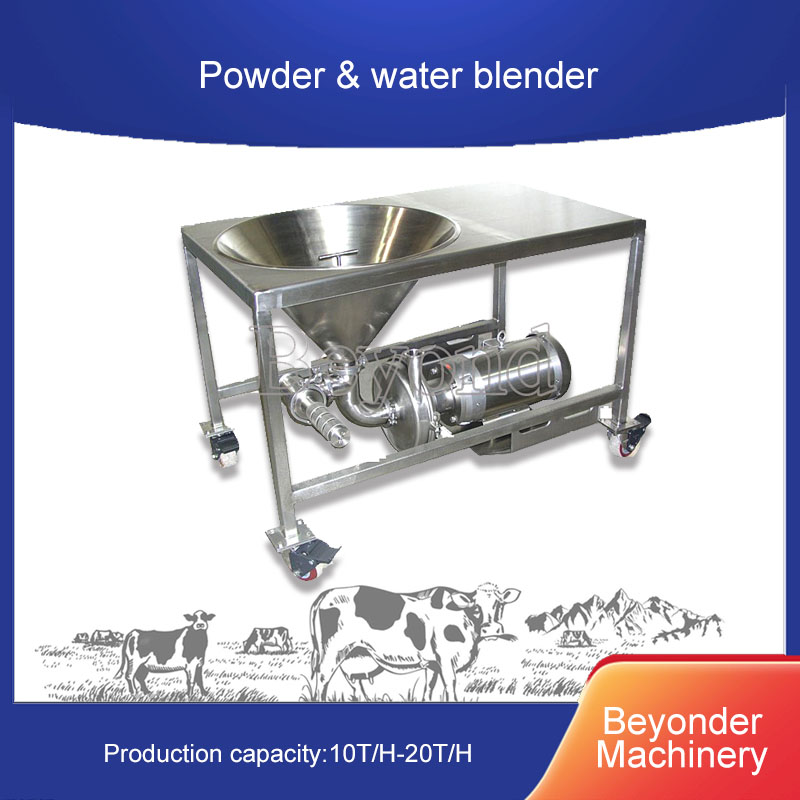

Description of water and powder blender:

The powder and water blender typically consists of the following components:

Hopper: A hopper or container where the dry powder is loaded. The size and capacity of the hopper may vary based on the specific application and production requirements.

Auger or Screw Conveyor: An auger or screw conveyor is used to transport the dry powder from the hopper into the blending chamber. It ensures a controlled and consistent flow of powder.

Mixing Chamber: The mixing chamber is where the dry powder and water are blended together. It is designed to create turbulence and agitation to ensure thorough mixing. The shape and design of the mixing chamber may vary depending on the application, but it generally includes baffles or impellers to enhance the mixing process.

Water Supply System: A water supply system provides a controlled flow of water into the mixing chamber. It can include pumps, valves, and flow meters to accurately measure and control the water-to-powder ratio.

Control Panel: A control panel with an operator interface allows users to set and monitor various parameters such as mixing time, water flow rate, and powder feed rate. It may also include safety features and alarms.

Discharge System: The blended mixture is discharged from the blender through an outlet. Depending on the application, the discharge system may include valves, pumps, or other equipment for transferring the mixture to the next stage of the process.

The powder and water blender is designed to ensure efficient dissolution of the powder particles and achieve a uniform consistency throughout the mixture. It is commonly used for applications such as reconstituting powdered ingredients, creating suspensions, and preparing liquid solutions for further processing or packaging. The blender can be customized based on the specific requirements of the product and production process, including capacity, material of construction, and automation level.

Application

Mainly used to hydration for milk powder(mix the powder with water); mix the coco powder to the milk; make whey solution; mix the wheat powder with water; produce salt water; pre-blend the yogurt or other dairy products etc.

Production capacity: 5T/H-20T/H|

Model |

Flow rate (T/H) |

Material dissolving capactiy |

Technical data |

External size(cm) (L×W×H) |

Power (KW) |

|

SFHE-10 |

10 |

800(Kg/H) |

SUS304 material, hard mechanical seal, outlet/inlet adapt SMS standard |

550*380*960 |

3 |

|

SFHE-20 |

20 |

1300(Kg/H) |

760*400*1015 |

5.5 |