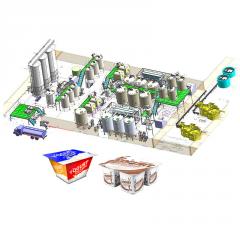

The description for the soy milk plant:

A soy milk processing line is a series of equipment and machinery used to produce soy milk from soybeans. The process typically involves several steps, including cleaning and soaking the soybeans, grinding and separating the pulp from the milk, heating and pasteurizing the milk, and packaging the final product.

Here is a breakdown of the main components of a soy milk processing line:

-

Soybean Cleaning: This step involves removing any impurities, such as stones, dirt, or debris, from the soybeans. This can be done using various cleaning equipment, such as a destoner, magnetic separator, and air cleaning machine.

-

Soaking and Grinding: The cleaned soybeans are soaked in water to soften them, making it easier to extract the milk. After soaking, the beans are ground into a slurry using a grinder or mill.

-

Separation: The ground soybean slurry is then passed through a separation device, such as a centrifuge or filter press, to separate the soy milk from the soybean pulp or solids. The separated milk is collected while the pulp is discarded or used for other purposes.

-

Heating and Pasteurization: The extracted soy milk is heated to a specific temperature to kill any harmful bacteria and ensure the milk is safe for consumption. This can be done using a heat exchanger or a pasteurization unit.

-

Flavoring and Fortification: Some manufacturers may choose to add flavors, sweeteners, or fortifying ingredients, such as calcium or vitamins, to enhance the taste and nutritional content of the soy milk. This step can involve mixing or blending equipment.

-

Homogenization: Homogenization is a process that breaks down fat droplets in the soy milk, creating a smoother and more consistent texture. This is typically achieved using a homogenizer.

-

Filtration and Sterilization: The soy milk may undergo further filtration to remove any remaining impurities or particles. Additionally, if the product is intended for long shelf life, it may be sterilized using methods such as ultra-high temperature (UHT) processing.

-

Packaging: The final step in the processing line involves packaging the soy milk into containers, such as cartons, bottles, or pouches. This can be done using filling and sealing machines.

Overall, a soy milk processing line combines various equipment and processes to efficiently produce high-quality soy milk. The specific design and configuration of the processing line may vary depending on the production capacity, desired product specifications, and automation level required by the manufacturer.

Raw materials and products of Soy Milk Production Line

1. Raw materials

The raw materials required for producing soy milk mainly include soybeans and other auxiliary raw materials. The following is a detailed list of raw materials:

•Soybeans: The main raw material, select high-quality, pest-free, and mildew-free soybeans, and make soy milk through soaking, grinding, filtering and other processes.

•Water: Used to soak soybeans and dilute soy milk, the water quality should be clean and pollution-free.

•Sugar: Such as sucrose and glucose syrup, used to increase the sweetness of soy milk and improve the taste.

•Stabilizer: Such as carrageenan and xanthan gum, used to improve the stability and taste of soy milk.

•Emulsifier: Such as lecithin and monoglyceride, used to improve the structure of soy milk and prevent stratification.

•Flavor: Such as vanilla flavor and coconut flavor, used to increase the flavor of soy milk.

•Color: Such as natural pigments (beetroot red, carotene), used to adjust the color of soy milk.

•Vitamins and minerals: Such as vitamin B12, calcium, iron, used to enhance the nutritional value of soy milk.

•Preservatives: Such as potassium sorbate, used to extend the shelf life of soy milk.

• Enzyme preparations: such as α-amylase, used to improve the taste and texture of soy milk.

2. Products

Soy milk production lines can produce many different types of soy milk products. Here are some common product types:

• Original soy milk: no sugar or other seasonings are added to retain the natural flavor of soy milk.

• Sweet soy milk: add an appropriate amount of sugar to increase sweetness, suitable for the taste of most consumers.

• Low-sugar soy milk: reduce the addition of sugar, suitable for people who need to control sugar intake.

• Sugar-free soy milk: use sugar substitutes (such as stevia, erythritol) instead of sucrose, suitable for diabetics or people on a low-sugar diet.

• Flavored soy milk: such as vanilla soy milk, coconut soy milk, chocolate soy milk, by adding different flavors and seasonings, provide a variety of flavor options.

• Fortified soy milk: add vitamins and minerals, such as vitamin B12, calcium, iron, to enhance the nutritional value of soy milk, suitable for nutritional supplements.

• Organic soy milk: use organic soybeans and organic ingredients, follow the standards of organic agriculture, and do not contain chemical pesticides and hormones.

•Ready-to-drink soy milk: pre-packaged ready-to-drink soy milk, which is convenient for consumers to drink directly and can be stored at room temperature or refrigerated.

Soybean milk production process:

1. Soybean lifting pump (the soaked soybean is mixed with water for lifting, the water returns to the original barrel, and the soybean remains in the hopper).

2. Soybean grinder (the soaked soybean is ground with water, and the soybean dregs are separated from the soybean milk).

3. Stir the bean dregs into a paste with water.

4. Suction pump (the soybeans are circulated by stainless steel centrifugal pump. The sanitary circulation pipeline valve can adjust the flow).

5. Second grinding of soybean meal.

6. The soymilk is pumped into the cooking barrel for cooking.

Features:

The machine is of all stainless steel structure, with a grinding system and soybean milk boiling. It is composed of a grinding unit, a suction pump, a soybean dregs pump, a soybean milk barrel, a soybean dregs barrel, a soybean milk boiling barrel, etc.

|

NO.

|

NAME

|

SIZE

|

MAIN TECHNOLOGY PARAMETER

|

UNIT

|

QTY

|

|

A

|

Grinding system

|

||||

|

A-1

|

Beans soaking trough

|

V=800L

|

SUS304 stainless steel, square shape, at bottom with filtration screen, water can be replaced, with big diameter outlet

|

set

|

4

|

|

A-2

|

Vacuum suck beans device

|

Q=200Kg/h

|

SUS304 stainless steel, with vacuum pump, vacuum pump etc.

|

unit

|

1

|

|

A-3

|

Soymilk and residue separator

|

Q=175Kg/h

|

the capacity is calculated by dry residue, filtration screen is 90 mesh

|

pcs

|

3

|

|

A-4

|

Milk and resisdue barrel with stirrer

|

|

SUS304,100L square tank, with standing agitator

|

pcs

|

2

|

|

A-5

|

Collector

|

V=150L

|

Material:SUS304

|

pcs

|

1

|

|

A-6

|

Centrifugal pump

|

Q=3T/h

|

SUS304 stainless steel, pump lift 24M,Good quality Mechanical Seal

|

pcs

|

3

|

|

A-7

|

Collector

|

V=400L

|

SUS304

|

pcs

|

1

|

|

A-8

|

Centrifugal pump

|

Q=3T/h

|

SUS304 stainless steel, pump lift 24M,Good quality Mechanical Seal

|

pcs

|

1

|

|

A-9

|

Soymilk cooker

|

Q=500L

|

SUS304,continuously cooking with three tanks

|

pcs

|

3

|

|

A-10

|

Cooked soymilk sieve

|

Q=3T/h

|

SUS304,with vibration motor, 100 mesh filtration screen

|

pcs

|

1

|

|

A-11

|

Collector

|

V=400L

|

Material:SUS304

|

pcs

|

1

|

|

A-12

|

Centrifugal pump

|

Q=5T/h

|

SUS304 stainless steel, pump lift 24M,Good quality Mechanical Seal

|

pcs

|

1

|

|

|

total A

|

|

|

|

|

|

B

|

BLENDING/HOMOGENIZE UNIT

|

||||

|

B-1

|

Blending tank

|

V=1500L

|

SUS304 stainless steel, heat insulated, top off- center vertical paddle type agitator, conical head, airtight manhole, breather

valve, digital show thermometer, glass tube level indicator, anti-eddy baffle, supporters with adjustable feet |

pcs

|

2

|

|

B-2-1

|

Milk pump

|

5T/h

|

SUS304 stainless steel, pump lift 24M, Good quality Mechanical Seal

|

pcs

|

1

|

|

B-2-2

|

Milk pump

|

3T/h

|

SUS304 stainless steel, pump lift 24M,Good quality Mechanical Seal

|

pcs

|

1

|

|

B-3

|

Powder and water blender

|

5T/h

|

Material is SUS304 stainless steel, use water for cooling, hard metal mechanical seal

|

pcs

|

1

|

|

B-4

|

Twin piping filter

|

3T/h

|

SUS304 stainless steel, two pipe, Stainless Steel Filter Element 100 Mesh

|

pcs

|

1

|

|

B-5

|

High pressure homogenizer

|

1T/h

|

60MPa, starting box included

|

pcs

|

1

|

|

|

Subtotal B

|

|

|

|

|

|

C

|

Filling unit

|

||||

|

C-1

|

High level tank

|

V=1000L

|

SUS304 stainless steel, heat insulated, top off- center vertical paddle type agitator, conical head, airtight manhole, breather

valve, digital show thermometer, glass tube level indicator, anti-eddy baffle, supporters with adjustable feet |

pcs

|

1

|

|

C-2

|

PP bottle filling machine

|

|

|

pcs

|

1

|

|

C-3

|

Retort system

|

|

Material is SUS304 stainless steel, include hot water pump, hot water tank, pipe and valves, manual control, include cages

|

pcs

|

1

|

|

C-4

|

Operation platform

|

|

Material SUS304 stainless steel, dimension: 2500*2500*2000,handrail, staircase, water drainage in central

|

pcs

|

1

|

|

C-5

|

Labeller

|

|

include conveyor

|

pcs

|

1

|

|

|

Subtotal C

|

|

|

|

|

|

D

|

CIP and hot water system

|

||||

|

D-1

|

Hot water tank

|

1500L

|

Material is SUS304 stainless steel, PU insulation, coil pipe heating, cone top head, sealed manhole, breath valve, digital show

thermometer, glass tube level indicator, anti-bubble plate, adjustable legs |

pcs

|

1

|

|

D-2

|

Temperature control system

|

|

Damplex temperature sensor, Burkert angle valve, spirax sarco water trap, temperature auto control

|

pcs

|

1

|

|

D-3

|

Hot water pump

|

5T/h

|

SUS304 stainless steel, pump lift 24M,Good quality Mechanical Seal

|

pcs

|

1

|

|

D-4

|

Combined type CIP system |

3×0.8T

|

Outer coat of SUS304 stainless steel material, inner shell of SUS316,single cleaning way, Concentrated acid/alkali tank adding

system based on US technology, 100L×2 acid/alkali Concentrate tanks |

unit

|

1

|

|

D-R

|

CIP return pump

|

20T/h

|

SUS304 stainless steel, pump lift 24M,Good quality Mechanical Seal

|

pcs

|

3

|

Soy Milk Processing Line Customized Solution

The soy milk processing line is designed to convert raw soybeans into a high-quality soy milk product. This process involves several stages, including cleaning, soaking, grinding, cooking, homogenizing, sterilizing, and packaging. Each stage can be customized based on the specific needs of the manufacturer regarding capacity, product type (e.g., flavored or fortified soy milk), and packaging requirements.

Throughout each step of production, quality control measures are implemented to ensure that the final product meets health standards and consumer expectations.

Automation Level: Depending on budget constraints and operational goals, varying levels of automation can be integrated into the production line for efficiency.