A fruit conveyor is a machine used for automated fruit processing and sorting. It uses a mechanical conveyor belt system to transport fruits from one location to another, in order to improve production efficiency and reduce labor costs.

The fruit conveyor usually consists of the following main components:

Conveyor belt system: The conveyor belt is the main medium for fruits to move inside the machine. It is made of wear-resistant materials and can transport fruits on horizontal or inclined tracks. The speed of the conveyor belt can be adjusted as needed to accommodate different types and sizes of fruits.

Alignment device: The alignment device is used to locate the position of fruits on the conveyor belt, ensuring that the fruits can be accurately grabbed and processed. This can be achieved through sensors, cameras, or mechanical devices.

Sorting device: The sorting device classifies and sorts fruits according to preset rules. This can be determined by characteristics such as color, size, and shape, and the fruits can be loaded into corresponding containers or conveyor belts.

Cleaning and impurity removal devices: Some fruit conveyors are also equipped with cleaning and impurity removal devices to remove dirt and impurities from the surface of fruits, ensuring their hygiene and quality.

Control system: The control system of the fruit conveyor is responsible for the operation and coordination of the entire machine. It can achieve automated operations through programming and monitor the working status of various components such as conveyor belt speed, alignment device, sorting device, etc.

The application range of fruit conveyor is very wide, which can be used in fruit planting bases, orchards, fruit juice processing factories, food processing factories, and other places. It can improve production efficiency, reduce labor costs, and ensure the quality and hygiene of fruits.

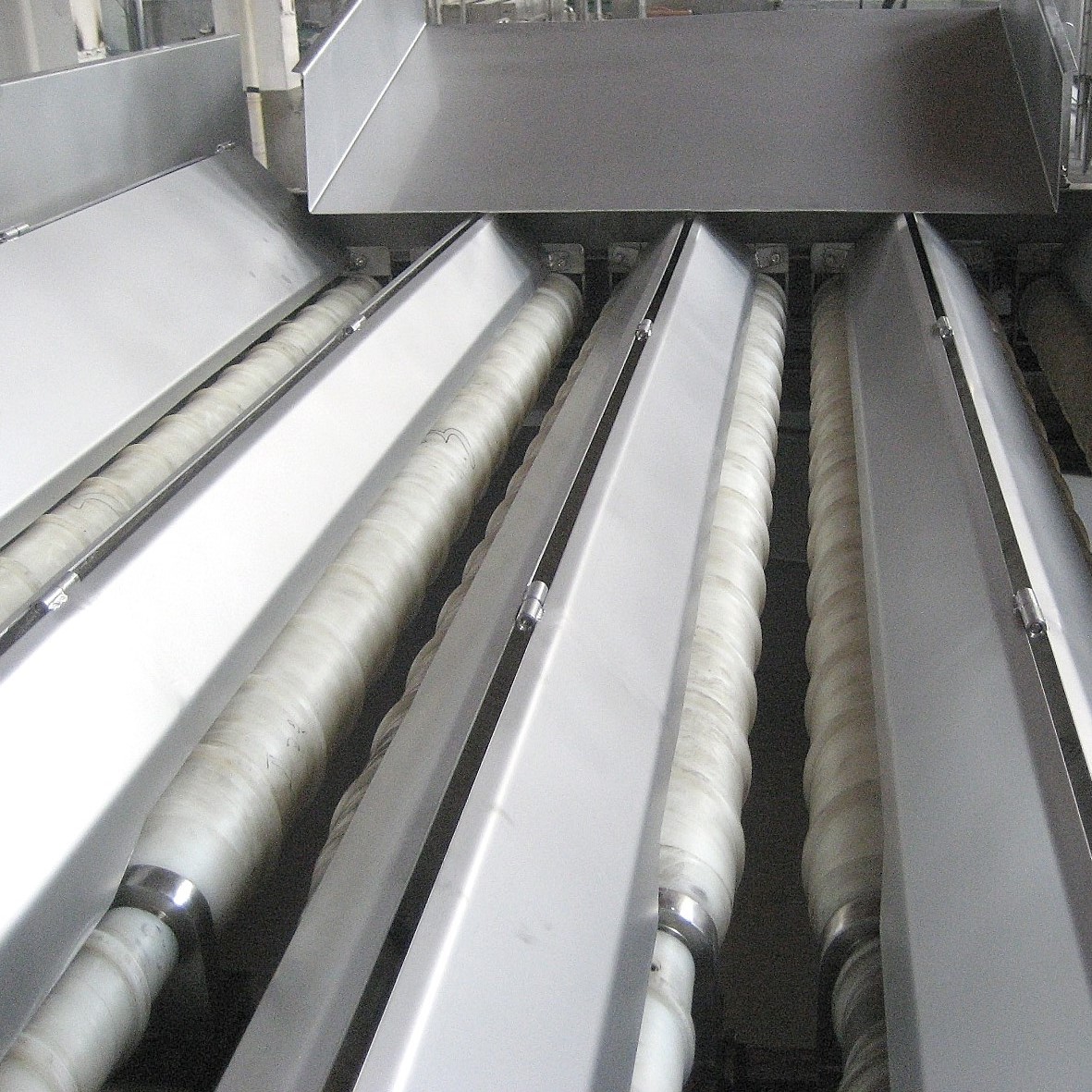

Description of screw conveyor

The spiral of the machine is driven forward by the motor; the moving and forwarding spiral makes the product move forward in the fixed machine body;

Construction type: horizontal, gradient and vertical type;

This machine has the following advantages as following: Simple structure; Small cross section; Convenient to transporting the fruits; Fruits can be loaded or discharged from different points;Widely used in transporting fruits, vegetables and the dregs.

Outer shell and the spiral are all made of SUS304 stainless steel, speed can be,stepless adjustable

Technical Parameter:

|

Name |

Transportation capacity |

(kw)

Power

|

|

||

|

line speed |

Capacity |

|

|||

|

LXSS-U150 |

50-112rpm |

4-8m3/H |

2-5m |

0.75 |

|

|

6-10m |

1.5 |

||||

|

11-15m |

2.2 |

||||

|

LXSS-U200 |

50-100rpm |

7-14m3/H |

2-5m |

1.5 |

|

|

6-10m |

3 |

||||

|

11-15m |

4 |

||||

|

LXSS-U250 |

45-90rpm |

13-24m3/H |

2-5m |

2.2 |

|

|

6-10m |

4 |

||||

|

11-15m |

5.5 |

||||

|

16-20 |

7.5 |

||||

|

LXSS-U300 |

40-80rpm |

16-32m3/H |

2-5m |

3 |

|

|

6-10m |

5.5 |

||||

|

11-15m |

7.5 |

||||

|

16-20 |

11 |

||||

|

LXSS-U350 |

36-72rpm |

26-52m3/H |

2-5m |

4 |

|

|

6-10m |

7.5 |

||||

|

11-15m |

11 |

||||

|

16-20 |

15 |

||||

|

LXSS-U400 |

36-72rpm |

30-60m3/H |

2-5m |

5.5 |

|

|

6-10m |

11 |

||||

|

11-15m |

15 |

||||

|

16-20 |

18.5 |

||||

The special feature of our screw conveyor is that we can add functions to it when needed by the process.

Single screw conveyors, complete conveying and storage systems are equipped for specific applications and can be customized if necessary.

The actual configuration of screw conveyor or mixer depends not only on the type of material to be treated (bulk), but also on humidity, temperature, zoning and actual process and mechanical requirements.

Our screw conveyor is famous for its reliability and improves the normal operation time of the system. Over the years, structures and parts have proved their firmness, while functions such as wear resistance, corrosion prevention or intermediate bearing can prolong the service life. In this way, the screw conveyor will remain in shape for a long time and become a stable factor in your production process.