Belt conveyor is a commonly used material handling equipment, which consists of conveyor belts, driving devices, tensioning devices, rollers, and other components. It mainly transports materials from one location to another through conveyor belts with the help of rollers and idlers.

Belt conveyors have the following characteristics:

Large transportation capacity: Belt conveyors can efficiently transport various materials, whether they are bulk or block materials. And its conveying capacity can be adjusted according to actual needs.

Long distance transportation: Due to the flexible combination of belt conveyors and the ability to achieve long-distance transportation through multi-stage connections, it is often possible to meet the transportation needs of different sites in industrial production.

Strong adaptability: Belt conveyors can adapt to different working environments and conditions. For example, in harsh environments, special designs such as dustproof, waterproof, and explosion-proof can be used; In high-temperature environments, high-temperature resistant materials can be used for manufacturing.

Stable operation: The belt conveyor adopts a driving device to drive the conveyor belt. The entire system has a simple structure, stable and reliable operation, and low noise.

Convenient maintenance: Due to the relatively simple structure of the belt conveyor, maintenance and upkeep are relatively convenient. Usually, it is mainly necessary to regularly inspect the tensioning device, rollers and other components of the equipment, and promptly repair worn or damaged areas to ensure their normal operation.

Overall, belt conveyors are an efficient, stable, and adaptable material handling equipment widely used in many industrial fields, such as mining, building materials, chemical engineering, metallurgy, etc.

Description of belt conveyor:

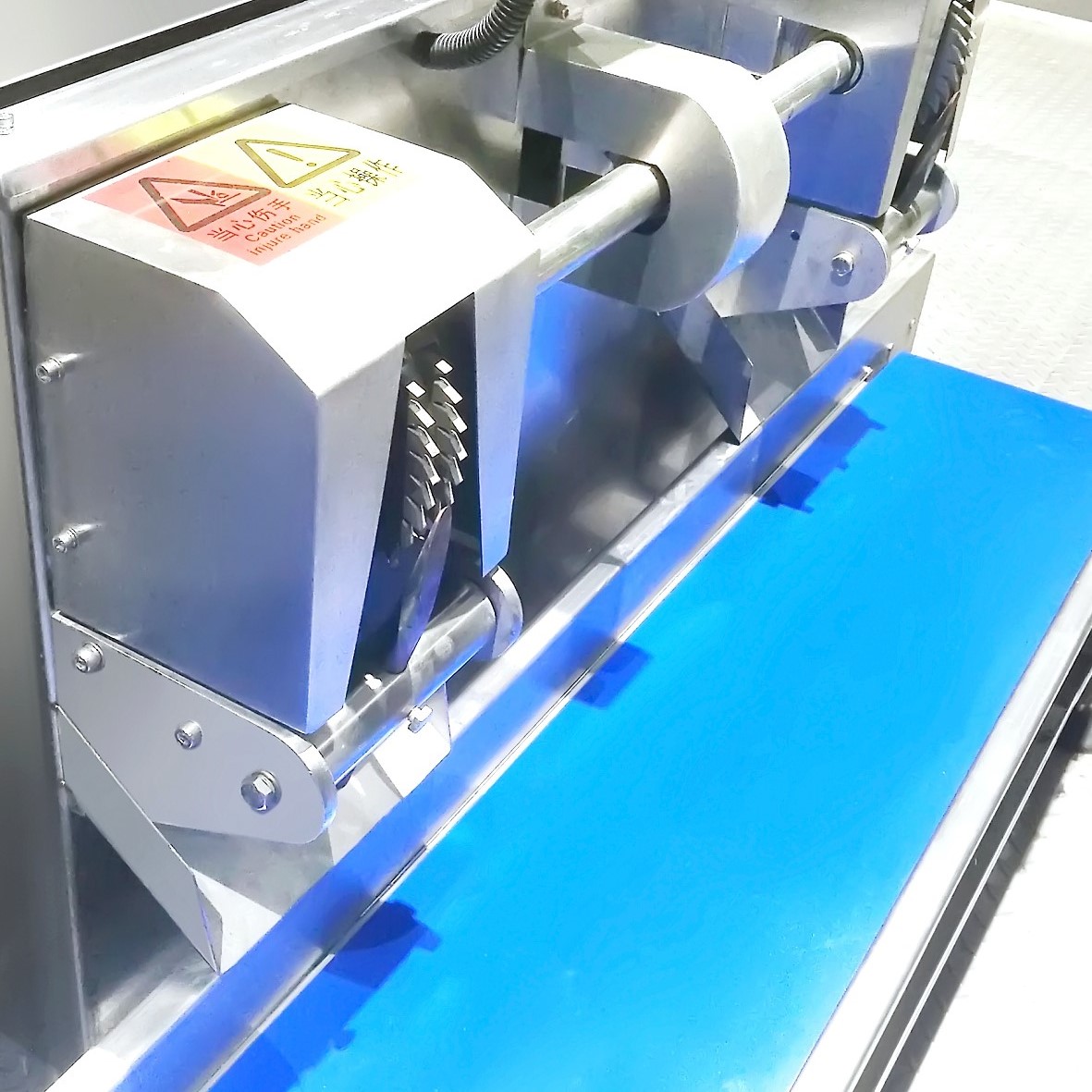

Adopts various kinds of sanitary belt and stainless steel side plate, so the structure is light and simple, which is much applicable for long distance transportation.The drive power is stepless adjustable;

The main roller is made of rubber with groove as direction guidance on it, and with the cooperation of the groove on the belt, so it can prevent the belt from deflection.

Extra ridding up device can be added onto the machine.

Framework is made of SUS304 stainless steel, material of the belt can be of PPC、PV or PU, speed can is stepless adjustable

Technical Parameter:

|

Name |

Description |

Transportation capacity |

(kw) |

||

|

line speed |

Capacity |

||||

|

PDSS-P250 |

0.2-0.6 m/sp> |

1-3m3/H |

5-10m |

0.55 |

|

|

10-20m |

0.75 |

||||

|

PDSS P400 |

0.2-0.6 m/s |

4-6m3/H |

5-10m |

0.75 |

|

|

10-20m |

1.1 |

||||

|

PDSS P800 |

0.2-0.6 m/s |

8-10m3/H |

5-10m |

1.1 |

|

|

10-20m |

2.2 |

||||

|

PDSS -P1000 |

0.2-0.6 m/s |

8-10m3/H |

5-10m |

1.5 |

|

|

10-20m |

3 |

||||

|

PDSS -P1200 |

0.2-0.6 m/s |

10-15m3/H |

5-10m |

2.2 |

|

|

10-20m |

4 |

||||

|

PDSS -P1500 |

0.2-0.6 m/s |

15-20m3/H |

5-10m |

3 |

|

|

10-20m |

5.5 |

||||

Belt conveyers, also known as conveyor belts, are a ubiquitous mode of material handling in numerous industries, owing to several distinctive advantages. Here are the key technical highlights of belt conveyer systems: