The coffee beverage processing line is a complex process of converting coffee raw materials into ready to drink coffee beverages, involving multiple steps and technical points, as well as specialized equipment.

The following is an overview of its basic principles, production process, technical points, and equipment introduction:

Overview of the principle: Coffee beverage processing mainly involves extracting effective ingredients from coffee (such as caffeine, aroma substances, etc.), then mixing them with other ingredients (such as sugar, dairy products, seasonings), and performing sterilization, filling, and other treatments to ensure product safety, deliciousness, and a long shelf life.

Production process

1. Raw material pretreatment: Select and clean coffee beans, and prepare other raw materials such as milk or non dairy alternatives.

2. Baking and Grinding: Coffee beans are finely roasted and ground into powder, releasing their aroma.

3. Extraction: Use hot water or steam to extract the essence from the coffee powder to get the coffee liquid.

4. Mixing and seasoning: Mix coffee with sugar, milk, stabilizers, seasonings, etc. to form a unique flavor base.

5. Homogenization and emulsification: Use a homogenizer to refine the fat particles in the mixture, improving taste and stability.

6. Sterilization and cooling: UHT ultra-high temperature instantaneous sterilization or pasteurization method is used to kill microorganisms, ensuring food safety, followed by rapid cooling.

7. Filling and capping: Pour the cooled coffee beverage into a pre disinfected container in a sterile environment and immediately cap it.

8. Packaging and Inspection: The finished products undergo final packaging and pass quality inspection to ensure appearance, taste, and safety standards.

Technical points

Temperature control: Strictly control the temperature during baking, extraction, and sterilization stages to preserve the best flavor.

Aseptic environment: The filling process needs to be operated in a highly sterile environment to extend the shelf life of the product Stable quality: Adding stabilizers and using appropriate homogenization and emulsification techniques to maintain product taste and stability.

Quick cooling: After sterilization, quickly cool to prevent excessive heat treatment from affecting the taste.

Equipment Introduction

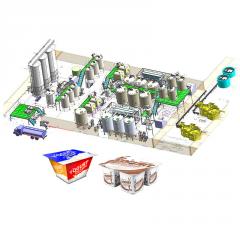

The coffee beverage processing line includes various professional equipment to achieve the entire process from raw material processing to finished product packaging. The following is the main equipment list:

1. Raw material processing equipment: • Coffee bean roaster: used for roasting coffee beans and releasing aroma Grinding machine: Grind roasted coffee beans into powder Extraction equipment: Hot water extraction or high-pressure extraction of coffee liquid.

2. Mixing and Modulation System: • Mixing Tank: Used for mixing coffee liquid with other ingredients such as sugar and creamer Homogenizer: makes the mixture uniform and delicate, enhancing the taste.

3. Filtration and purification equipment: • Filter: removes impurities to ensure the purity of the liquid. • Degassing machine: removes bubbles from the liquid to prevent oxidation from affecting quality.

4. Heating and cooling system: • Heater: Heat the liquid to the appropriate processing temperature. • Cooling equipment: Quickly cool down and prepare for subsequent filling.

5. Sterilization and filling equipment: Sterilization machine: such as UHT (Ultra High Temperature Instant Sterilization) equipment, to ensure product safety and sterility Filling machine: Automatic quantitative filling of coffee beverages into packaging containers.

6. Capping and packaging machine: • Capping machine: seals containers to keep products fresh. • Packaging machine: automatic packaging, such as plastic film wrapping, paper box packaging, etc.

7. Automation and control system: • PLC control system: Central control of the operation of the entire production line. • Sensors and actuators: monitor each link and automatically adjust.

8. Post processing and inspection equipment: • Inspection equipment: such as visual inspection systems, to ensure product quality and packaging integrity Coding inkjet printer: Print production date, batch number and other information on the packaging.

9. Conveyor and Storage System: • Conveyor Belt: Connecting various equipment to automatically transport products. • Storage shelves: Temporary storage of finished products, waiting to be released from the warehouse.

The above equipment may be adjusted or modified based on specific production needs and scale. The selection of each stage needs to consider efficiency, cost, and the quality requirements of the final product.

| Name |

Model

|

Main technical parameters |

QTY

(piece) |

|

| Extracting and filtering system |

|

|||

| Extracting tank |

600L

|

SUS 304, insulation, top central paddle mixer, sealed manhols, bottom outlet and discharge,oval head and bottom conical cover angle is more than 45 degree,cylinder stator full auto on-off at the discharge and the self-lock device |

2

|

|

| Centrifugal pump |

10T/h

|

SUS 304, H=24m, high-quality mechanical seal, ABB motor |

1

|

|

| Duplex cloth filter |

10T/h

|

SUS 304, Duplex type, 200mesh |

1

|

|

| Plate cooler |

10T/h

|

SUS304, three stages, temperature cooling from 95-15degree, first stage, cooling by RO water, second stage, cooling by tower water, third stage ice water |

1

|

|

|

Tea water storage tank |

2000L

|

material SUS 304, single layer, conical cover,Airtight manhole, breathing valve, digital display thermometer |

1

|

|

| Centrifugal pump |

5T/H

|

SUS 304, H=24m, high-quality mechanical seal, ABB motor |

1

|

|

| Duplex tube filter |

5T/H

|

SUS 304, Duplex type, 200mesh |

1

|

|

| Disk centrifuge |

3T/h

|

self discharge |

1

|

|

| CIP return pump |

20T/h

|

SUS304, lift:20m, mechanical seal |

2

|

|

| Sugar desolving and storaging system |

|

|||

| High speed blender |

500L

|

SUS304,insulation,bottom high speed emusifying head, digital display thermometer |

1

|

|

| Centrifugal pump |

10T/H

|

SUS 304, H=24m, high-quality mechanical seal, ABB motor |

1

|

|

| Duplex tube filter |

10T/h

|

SUS 304, Duplex type |

1

|

|

| Plate cooler |

10T/h

|

SUS 304, one stage, cooling from 80 degree to 40 degree |

1

|

|

| Diatomite filter |

Q=5t/h

|

Containing the precoat tank and precoat pump |

1

|

|

| Sugar liquor |

1500L

|

SUS 304, single layer, conical cover, sealed manhole, breathing value, digital display themometer |

2

|

|

| Centrifugal pump |

10T/h

|

SUS 304, H=24m, high-quality mechanical seal, ABB motor |

1

|

|

| CIP return pump |

20T/h

|

SUS304, lift:20m, mechanical seal |

1

|

|

| Mixing system |

|

|||

| Mixing tank |

3000L

|

SUS 304, single layer,top off-set stirring, sealed manhole, digital display themometer, conical cover |

2

|

|

| Centrifugal pump |

5T/h

|

SUS 304, H=24m, high-quality mechanical seal, ABB motor |

1

|

|

| Duplex cloth filter |

5T/h

|

SUS 304, Duplex type, 200mesh |

1

|

|

| CIP return pump |

20T/h

|

SUS304, lift:20m, mechanical seal |

|

|

| Sterilizing system |

|

|||

|

Tubular sterilizer |

3000L

|

Tubular type, sterilizing temperature 120 degree, 15 seconds, PLC full automatic control, hot filling |

1

|

|

| E. Hot water system | ||||

| Hot water tank |

3000L

|

SUS 304, insulation, conical cover, sealed manhole, breathing value, digital display themometer |

1

|

|

| centrifugal pump |

10T/h

|

SUS 304, H=24m, high-quality mechanical seal |

1

|

|

| Plate cooler |

10T/h

|

SUS304,one stage |

1

|

|

| Temperature control system |

10T/h

|

Spirax sarco steam reduced pressure, control system |

1

|

|

| Semi automatic CIP system | ||||

| Full-automatic CIP system | 3×2T | SUS 304, inner layer 316,single circuit,Germany Burkert temperature control system, America concentrate acid and alkali adding system 100L*2 tanks, automatic temperature control,and automatic acidity , Washing process automatic control, fault alarm concentrated acid/alkali tanks |

1

|

|

| Installation system | ||||

| Stainless steel piping unit | Including the pipe lines as well as the CIP system before the filling, follows SMS standard pipe size: ¢63,¢51,¢38 |

1

|

||

| Power piping unit | Power line and heat preservation for the main line excluding filling system |

1

|

||

| Electric control cabinet | Control cabinet for main line excluding filling part |

1

|

||

| Electric wires and connecting material | Electric wires and connecting material for main line excluding filling part |

1

|

||

The installation and debugging of a coffee beverage processing line is a professional and meticulous task, typically involving the following key steps:

1. Preliminary planning: • Confirm the factory layout to ensure the smoothness and efficiency of the production line Prepare necessary infrastructure such as water, electricity, gas supply, drainage system, air purification system, etc Communicate with suppliers to determine the specific configuration and technical requirements of the equipment.

2. On site preparation: Clean the installation area to ensure that the ground is flat, dust-free, and meets hygiene standards Mark the installation positions of each device and reserve sufficient operating space and maintenance channels.

3. Equipment entry and assembly: Install each unit of equipment one by one according to the planned sequence, such as extractors, mixing tanks, homogenizers, sterilizers, filling machines, etc Perform mechanical assembly to ensure that all components are securely connected and comply with safety production standards Install electrical control system and pipelines (water pipes, gas pipes, cables, etc.), conduct preliminary wiring and inspection.

4. System debugging: • Single machine debugging: Start each device one by one, check if it is running normally, and adjust the parameters to the optimal state System integration testing: Test the collaborative operation capability of the entire production line to ensure smooth connection of each link, without leakage, blockage, or other issues Calibration of key parameters such as temperature, pressure, and flow rate to meet the predetermined production process requirements.

5. Aseptic testing and cleaning validation: • Perform CIP (Cleaning in Place) and SIP (Sterilization in Place) procedures to verify the effectiveness of cleaning and sterilization, ensuring a sterile production environment Test water quality, air, etc. to ensure compliance with food safety standards.

6. Trial production and optimization: Conduct small-scale trial production, collect data, evaluate product quality and production efficiency Adjust process parameters or equipment settings based on trial production results until the predetermined production capacity and quality targets are achieved.

7. Training and Acceptance: Provide training to operators on equipment operation, maintenance, and safety regulations Organize final acceptance to ensure that the production line meets design requirements and regulatory standards.

8. After sales service and continuous support.

The informatization of coffee beverage processing lines refers to the integration of information technology (IT) into the production process to achieve automation control, data collection and analysis, quality traceability, remote monitoring, and other functions, in order to improve production efficiency, reduce human errors, and optimize resource allocation.

Specifically, it includes the following aspects:

1. Automation control system (PLC/SCADA): Using programmable logic controllers (PLC) and monitoring and data acquisition systems (SCADA), the equipment is automatically controlled to monitor production status in real-time, such as temperature, pressure, flow rate, and other parameters, and adjust them in a timely manner to ensure production quality.

2. Enterprise Resource Planning System (ERP): Integrate internal resources of the enterprise, including information management of various links such as finance, procurement, inventory, sales, etc., to improve overall operational efficiency and reduce costs.

3. Manufacturing Execution System (MES): Located at the level between ERP and workshop control, it focuses on the production execution level, including production scheduling, material tracking, work order issuance, real-time data collection and analysis, ensuring transparency and controllability of the production process.

4. Quality Management System (QMS): Implement full chain quality monitoring from raw material storage to finished product delivery, including raw material inspection, production process control, finished product inspection, etc., supporting batch tracking and recall management.

5. Application of Internet of Things (IoT) technology: Collecting device operation data through sensors, RFID and other technologies to achieve interconnectivity between devices, remote monitoring and fault warning, and improve maintenance efficiency.

6. Big Data and Artificial Intelligence (AI): Using big data analysis techniques to deeply mine production data, identify potential problems and optimization points. By combining AI algorithms, it is possible to predict production trends, optimize production plans, and even achieve intelligent fault diagnosis and preventive maintenance.

7. Cloud computing platform: Utilizing cloud services to store massive amounts of data, providing elastic computing resources, supporting remote access and multi location collaboration, facilitating management and analysis of production data.

Implementing these information technology measures can not only enhance the intelligence level of coffee beverage processing lines, but also provide data support for enterprise decision-making and promote the transformation of enterprises towards intelligent manufacturing.

The final product of the coffee beverage processing line is ready to drink coffee beverages, which are very diverse in the market and mainly include the following types:

1. Bottled/canned coffee: the most common form, suitable for retail in supermarkets and convenience stores, and also easy to carry and drink.

2. Boxed coffee beverages: packaged in paper or composite materials, emphasizing environmental protection and convenience.

3. PET bottled iced coffee/latte: suitable for the cold drink market, emphasizing refreshing taste and quick consumption.

4. Aluminum canned cold brew/espresso: Targeting the high-end market, emphasizing quality and freshness preservation.

5. Ready to drink latte/cappuccino: contains a milk froth layer that mimics the layering and flavor of freshly ground coffee.

6. Low sugar/sugar free/organic coffee drinks: catering to health trends and targeting specific consumer groups.

7. Functional coffee drinks: added vitamins, dietary fiber, etc., emphasizing refreshing and other health benefits.

They undergo strict quality control before leaving the factory to ensure compliance with food safety standards, and are distributed to various sales channels through efficient logistics chains to meet the drinking needs of consumers in different scenarios.

Designing a coffee beverage production line requires comprehensive consideration of production processes, equipment selection, raw material and product characteristics, as well as the layout of the production line. Here is a detailed customization plan:

1. Preparation of raw materials for production process

• Raw material reception and storage: Receive coffee beans, water, and other auxiliary materials, store them in a suitable environment, and avoid spoilage.

• Preprocessing: Baking, grinding, and other preprocessing steps are performed on coffee beans to improve extraction efficiency and product quality.

extract

Extraction: Use an extraction machine to bring the ground coffee powder into contact with hot water to extract the coffee liquid.

• Filtration: Use a filter to separate the solid residue in the coffee liquid and obtain a clear coffee liquid.

Allocation

• Preparation: Mix the extracted coffee liquid in a certain proportion, and add appropriate amounts of water, sugar, creamer, stabilizer, vitamins, and other ingredients according to the formula to adjust the taste and nutritional content.

Homogenization

Homogenization: Use a homogenizer to refine the particles in the mixture, making it more uniform and improving taste and stability.

sterilization

Sterilization: Through high-temperature instantaneous sterilization (UHT) or pasteurization treatment, harmful microorganisms are killed to ensure the safety of the product.

cooling

• Cooling: Quickly cool the sterilized mixture to a suitable temperature to prevent bacterial growth.

filling

• Filling: Fill the cooled mixture into bottles, cans, or bags to ensure good sealing and prevent contamination.

seal

Sealing: Use a sealing machine to seal the packaging container to ensure sealing performance.

Labeling

Labeling: Attach labels to packaging containers, indicating product information, production date, shelf life, etc.

packing

• Packaging: Packaging the finished product for easy transportation and sales.

test

• Inspection: Conduct quality inspection on finished products to ensure compliance with relevant standards and regulatory requirements.

Storage

• Storage: Store qualified products in a suitable environment, usually a cool and dry place, to ensure product quality and shelf life.

2. Equipment selection: Main equipment

Raw material receiving and storage equipment: storage tanks, cold storage.

Pre processing equipment: baking machine, grinding machine.

Extraction equipment: extraction machine, filter.

• Mixing equipment: mixing tank, mixer.

Homogenization equipment: Homogenizer.

Sterilization equipment: UHT sterilizer, pasteurizer.

Cooling equipment: cooling tower, cooling tunnel.

Filling equipment: filling machine.

Sealing equipment: sealing machine.

Labeling equipment: Labeling machine.

• Packaging equipment: packaging machine.

Inspection equipment: quality testing instruments.

Storage equipment: warehouse, cold storage.

3. Raw materials and product raw materials

• Coffee beans: Fresh and high-quality coffee beans, choose different types of coffee beans according to product requirements.

• Water: Pure water used for extraction and blending.

• Accessories: sugar, creamer, stabilizer, vitamins, etc., used to adjust taste and nutritional content.

product

• Regular coffee beverages: Basic coffee beverage products.

Functional coffee beverages: add specific functional ingredients such as antioxidants, vitamin C, etc.

• Low sugar or sugar free coffee drinks: suitable for diabetes patients or consumers with strong health awareness.

• Special flavored coffee drinks: add special flavors such as vanilla and chocolate to meet different market demands.

4. Customized demand production capacity

Capacity selection: Select equipment with appropriate capacity based on the size and demand of the factory.

Flexibility: Design adjustable production lines to meet the production needs of different products.

Product diversity

Multi flavor production: Design production lines for multiple flavors to meet the needs of different markets.

Special requirements: Provide coffee beverage production lines with special needs such as organic and low sugar.

Degree of automation

• Automation level: Select different levels of automation equipment based on budget and management needs.

Information management: Introduce information management systems to improve production efficiency and management level.

Environmental requirements

Wastewater treatment: Design a wastewater treatment system that complies with local environmental regulations.

• Waste management: Reasonably handle the waste generated during the production process.

hygienic standard

GMP and HACCP: Ensure that all equipment and facilities comply with hygiene standards such as GMP and HACCP.

• Cleaning and maintenance: Regularly clean and maintain the equipment to ensure the hygiene of the production environment.

5. Design and plan the overall layout

Raw material receiving area: used for receiving and inspecting the quality of raw materials.

Storage area: used for storing raw materials and finished products.

Processing area: including pre-treatment, extraction, blending, homogenization, sterilization, cooling and other processes.

Filling area: used for filling and sealing finished products.

Labeling area: used for labeling finished products.

• Packaging area: used for the outer packaging of finished products.

Finished product storage area: used for storing finished products and preparing them for shipment.

• Laboratory: used for quality control and testing.

Office and Rest Area: Provides a place for employees to work and rest.

6. Technical support

Automation and informatization: Introduce automated production lines and information management systems to improve production efficiency and management level.

• Training: Regularly train employees to ensure they master the latest technology and operating procedures.

After sales service: Provide comprehensive after-sales service and technical support to ensure the normal operation of the production line.