A water bath pasteurizer is a piece of equipment used to pasteurize food and beverage products. It is commonly used in the food industry to heat treat products such as fruit juices, dairy products, sauces, and soups.

The pasteurization process involves heating the product to a specific temperature for a set period of time in order to kill harmful bacteria, yeasts, and molds, while still preserving the quality and flavor of the product.

A water bath pasteurizer typically consists of a stainless steel tank or vessel filled with water. The product to be pasteurized is placed in sealed containers or bags and submerged in the water bath. The water is heated to the desired pasteurization temperature using electric heaters or steam coils.

The pasteurization time and temperature can vary depending on the specific product being processed. This information is usually provided by food safety regulations or guidelines. Once the desired temperature is reached, the product is held at that temperature for the designated time to ensure effective pasteurization.

Water bath pasteurizers often have built-in temperature controls and timers to automate the process and maintain precise pasteurization conditions. They may also have agitation systems to ensure even heat distribution and prevent hot spots.

After the pasteurization process is complete, the product is cooled down rapidly to inhibit any potential recontamination. This can be done by transferring the product to a cooling tank or using a heat exchanger.

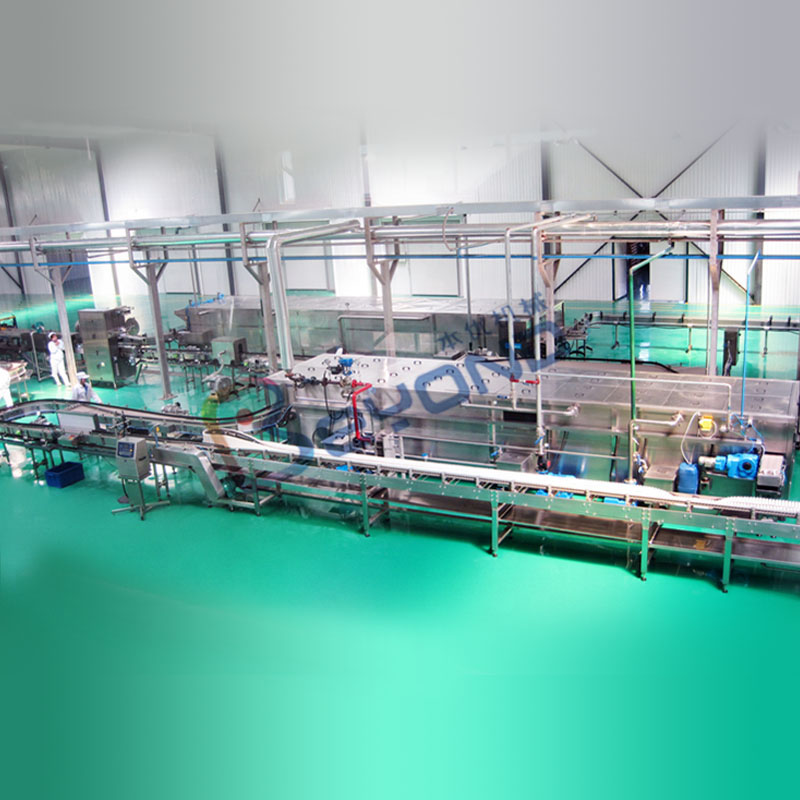

Water bath pasteurizers are designed to meet food safety standards and provide an efficient and reliable method of pasteurizing various food and beverage products. They are widely used in commercial food processing facilities and can help extend the shelf life of perishable goods while ensuring consumer safety.

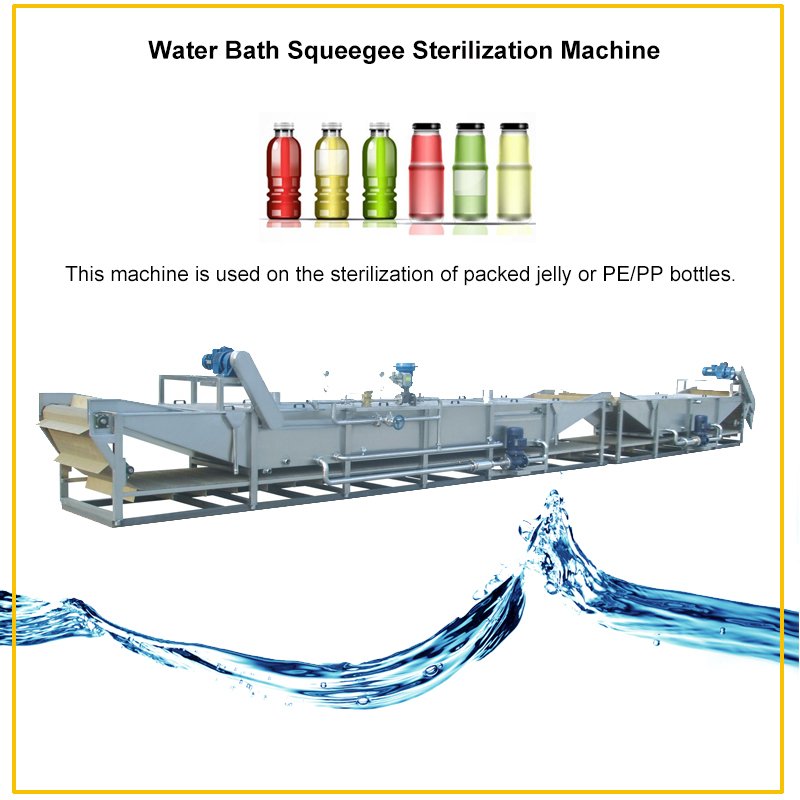

Usage:

This machine is used on the sterilization of packed jelly or PE/PP bottles.

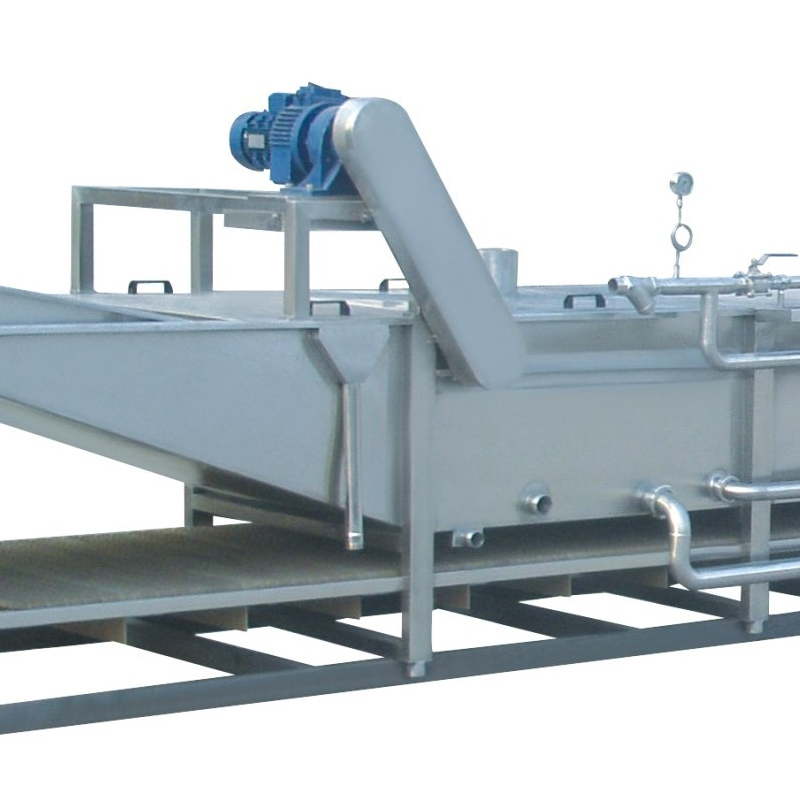

Structure:

Water bath squeegee sterilization machine is made of SUS304 stainless steel, 2B surface, which is composed of transfer squeegee, machine body, piping system, electricity controller cabinet. Products can be transferred into pointed position by roller chain. The sterilization time can be regulated by changing the transducer rotating speed.

| Volume | Tank design | |

| Single layer tank | Insulated tank | |

| 500L | T=2.5mm | T1=2.5mm,T2=1.5mm,T0=50mm |

| 1000L | T=2.5mm | T1=2.5mm,T2=1.5mm,T0=50mm |

| 1500L | T=2.5mm | T1=2.5mm,T2=1.5mm,T0=50mm |

| 2000L | T=2.5mm | T1=2.5mm,T2=1.5mm,T0=50mm |

| 2500L | T=2.5mm | T1=2.5mm,T2=1.5mm,T0=50mm |

| 3000L | T=3.0mm | T1=3.0mm,T2=2.0mm,T0=60mm |

| 4000L | T=3.0mm | T1=3.0mm,T2=2.0mm,T0=60mm |

| 5000L | T=3.0mm | T1=3.0mm,T2=2.0mm,T0=60mm |

| 6000L | T=3.0mm | T1=3.0mm,T2=2.0mm,T0=60mm |

| 7000L | T=3.0mm | T1=3.0mm,T2=2.0mm,T0=60mm |

| 8000L | T=3.0mm | T1=3.0mm,T2=2.0mm,T0=60mm |

| 9000L | T=3.0mm | T1=3.0mm,T2=2.0mm,T0=60mm |

| 10000L | T=3.0mm | T1=3.0mm,T2=2.0mm,T0=60mm |

Condition: New

Brand name: Shanghai Beyond;

Type: whole processing Line/turnkey project/fruit and vegetables processing/dairy processing/beverage processing

Voltage: 220v/380v

Power(W): 100-200 kw

Weight: Different size different weight/customized

Dimension(L*W*H): Different size different dimension/customized

Certification: CE&ISO

Warranty: 12 months/1 year

After-sales Service Provided: Engineers available to service machinery overseas

Main material: SUS304 or SUS316

Control type: automatic, semi-automatic

energy consumption: Low consumption with high efficiency

capacity: 500-10000 L/H-customized

installation period: 1-3 months

Period time: 30 days-120 days

Cups material: pouches, paper box, glass bottle, pet bottle, glass bottle

Product storage condition: room temperature; low temperature;

Operation

•Remove the containers from the water bath and place them on a conveyer belt or rack for further processing or storage.