A dual layer storage tank is a type of storage tank that consists of two layers or walls. The inner layer is the primary containment layer, which holds and stores the substance being stored, such as liquids or gases. The outer layer acts as a secondary containment layer and serves as a protective barrier against leaks, spills, or potential damage to the inner layer.

The purpose of the dual layer design is to provide an extra level of safety and protection. In case the inner layer develops a leak or gets damaged, the outer layer will prevent the substance from leaking into the environment. This reduces the risk of contamination and environmental damage.

Dual layer storage tanks are commonly used to store hazardous substances, chemicals, petroleum products, and other potentially dangerous materials. They are designed to meet strict safety standards and regulations to ensure the protection of both the stored substance and the surrounding environment.

These tanks are usually made of materials like steel with a corrosion-resistant coating. The dual layer construction and materials used make them strong, durable, and resistant to corrosion, which further enhances the safety and longevity of the tanks.

Overall, dual layer storage tanks are an essential component of industries that deal with hazardous materials, providing a reliable and secure solution for storing and handling these substances.

Use: Most applicable for storage and mixing of all kinds of liquid products in dairy products, juice, beer and brew, chemistry, and biology engineering;

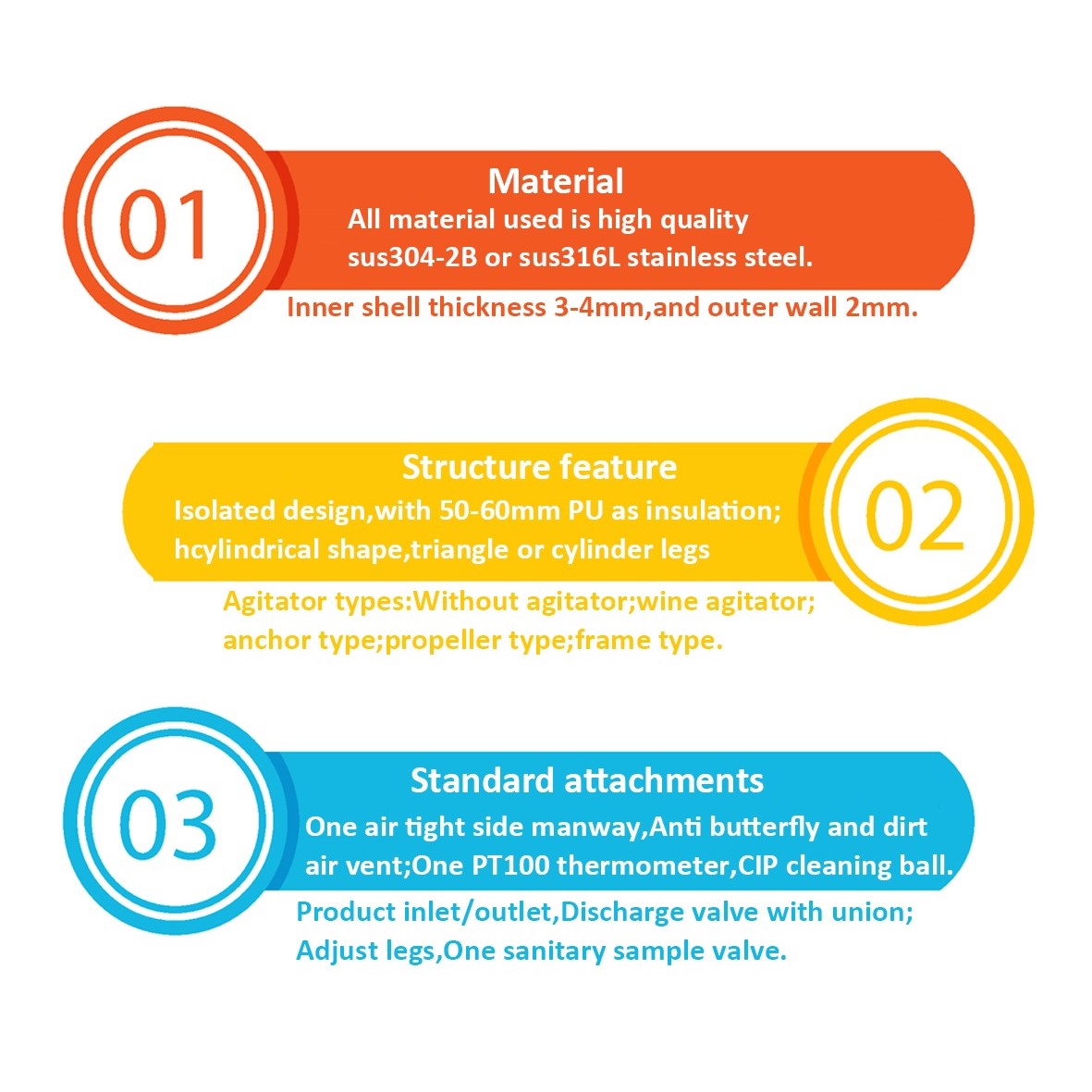

Material: All material used is high quality sus304-2B stainless steel, inner shell thicknessδ=3mm and outer wall 2mm;

Structure feature: Isolated design(double layer),with 60mm PU as insulation; cylindrical shape, triangle or cylinder legs.

Agitator types: Without agitator; wing agitator; anchor type; propeller type; frame type

Technical parameter

|

Model |

Diameter |

External diameter |

Heightmm |

Insulationδ |

Diameter of inlet/outlet |

|

BYSG-500 |

φ500 |

800 |

2140 |

50 |

φ38 / φ51 |

|

BYSG-1 |

φ1000 |

1050 |

2380 |

50 |

φ38 / φ51 |

|

BYSG-1.5 |

φ1500 |

1180 |

2550 |

50 |

φ38 / φ51 |

|

BYSG-2 |

φ2000 |

1340 |

2760 |

50 |

φ38 / φ51 |

|

BYSG-2.5 |

φ2500 |

1420 |

2940 |

50 |

φ38 / φ51 |

|

BYSG-3 |

φ3000 |

1540 |

3050 |

50 |

φ38 / φ51 |

|

BYSG-4 |

φ4000 |

1650 |

3200 |

50 |

φ38 / φ51 |

|

BYSG-5 |

φ5000 |

1780 |

3250 |

50 |

φ38 / φ51 |

|

BYSG-6 |

φ6000 |

1900 |

3350 |

50 |

φ38 / φ51 |

|

BYSG-8 |

φ8000 |

2060 |

3800 |

60 |

φ65 / φ51 |

|

BYSG-10 |

φ10000 |

2300 |

4050 |

60 |

φ65 / φ51 |

|

BYSG-12 |

φ12000 |

2520 |

4450 |

60 |

φ65 / φ51 |

|

BYSG-15 |

φ15000 |

2540 |

4700 |

60 |

φ65 / φ51 |

Standar attachments

a) one air tight side manway;

b) anti butterfly and dirt air vent;

c) One PT100 thermometer, temperature indication range 0~100;

d) CIP cleaning ball;

e)Discharge valve with union;

f) one sanitary sample valve;

g) product inlet/outlet