A pineapple processing line is a series of equipment and machinery used to process pineapples from harvesting to packaging. The line typically includes the following steps:

Harvesting: Pineapples are picked when they are ripe and ready for processing.

Washing: The harvested pineapples are washed to remove any dirt, debris, or pesticides. This can be done using water sprays or in large washing tanks.

Sorting and Grading: Pineapples are sorted based on size, shape, and quality. This step ensures that only the best pineapples move forward in the processing line.

Peeling and Coring: The outer skin and crown of the pineapple are removed using specialized peeling and coring machines. This step leaves behind the edible fruit.

Slicing or Dicing: Depending on the desired end product, pineapples may be sliced into rings or diced into smaller pieces. This can be done manually or using automated slicing machines.

Blanching: The sliced or diced pineapples are blanched in hot water or steam for a short period of time. This helps in preserving the color and texture of the fruit.

Cooling: After blanching, pineapples are cooled down rapidly using cold water or air. This prevents overcooking and maintains the freshness of the fruit.

Packaging: The processed pineapples are packed into containers or bags for distribution. Packaging can vary depending on the final product, such as canned pineapples, frozen pineapples, or fresh cut fruit.

Quality Control: Throughout the entire processing line, quality control measures are implemented to ensure that the pineapples meet the required standards for taste, appearance, and safety.

Storage and Distribution: The packaged pineapples are stored in appropriate conditions, such as cold storage facilities, before being distributed to retailers or consumers.

Overall, a pineapple processing line streamlines the entire process of handling pineapples, ensuring efficiency, quality, and consistency in the final product.

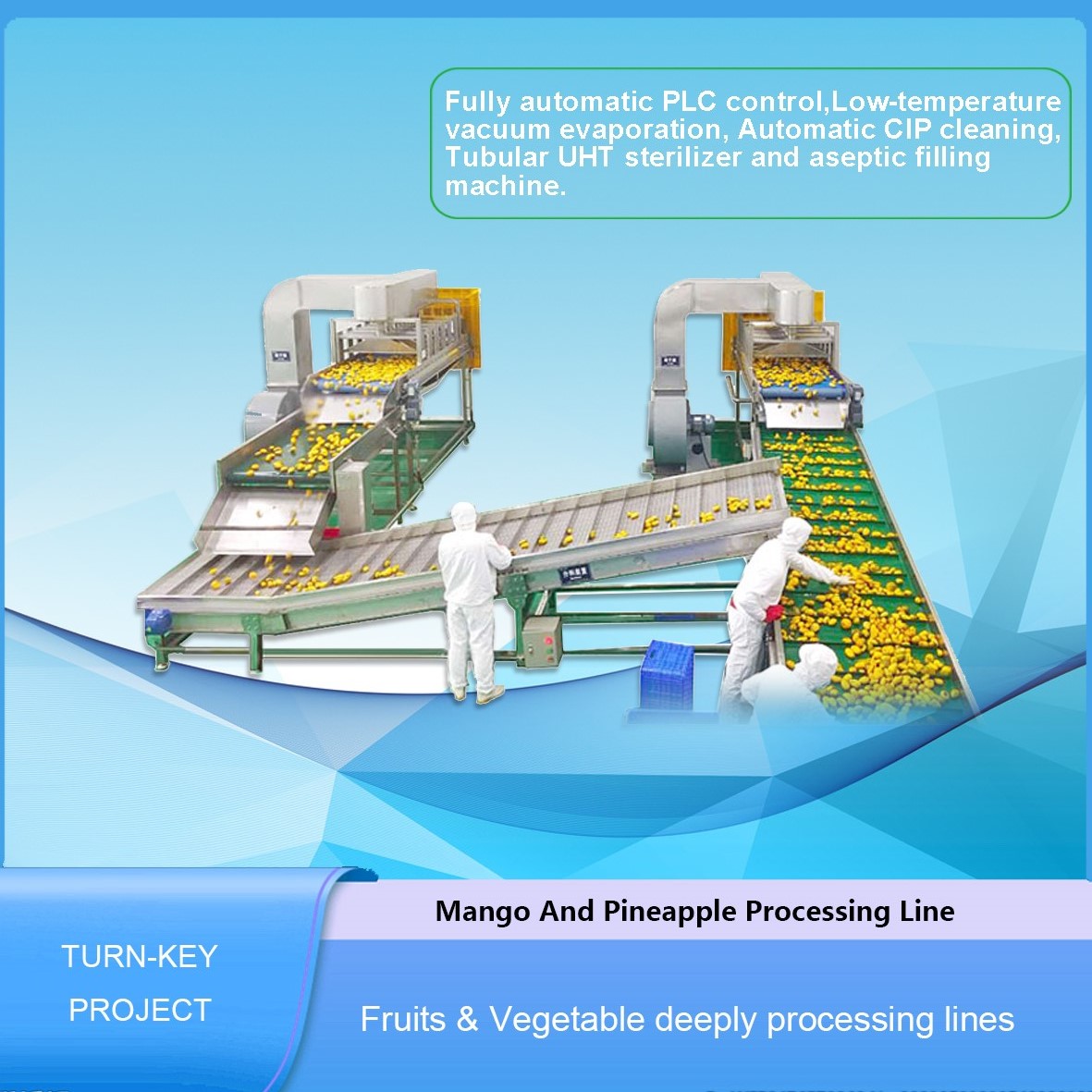

Pineapple Processing plant features:

1、The treatment capacity ranges from 60 tons / day to 1500 tons / day.

2、It can handle fruits with similar characteristics.

3、Pineapple juice yield can be effectively improved by using pineapple efficient peeling machine.

4、Using belt type juicer to improve the juice extraction efficiency and juice yield of pineapple.

5、It can realize PLC control in the whole production process, save labor and facilitate production management.

6、Vacuum concentration at low temperature can retain flavor and nutrients to the maximum extent and save energy.

7、Aseptic tube sterilization and aseptic barrel filling can produce high quality aseptic juice products.

8、Full automatic CIP cleaning ensures the food hygiene and safety requirements of the whole line equipment.

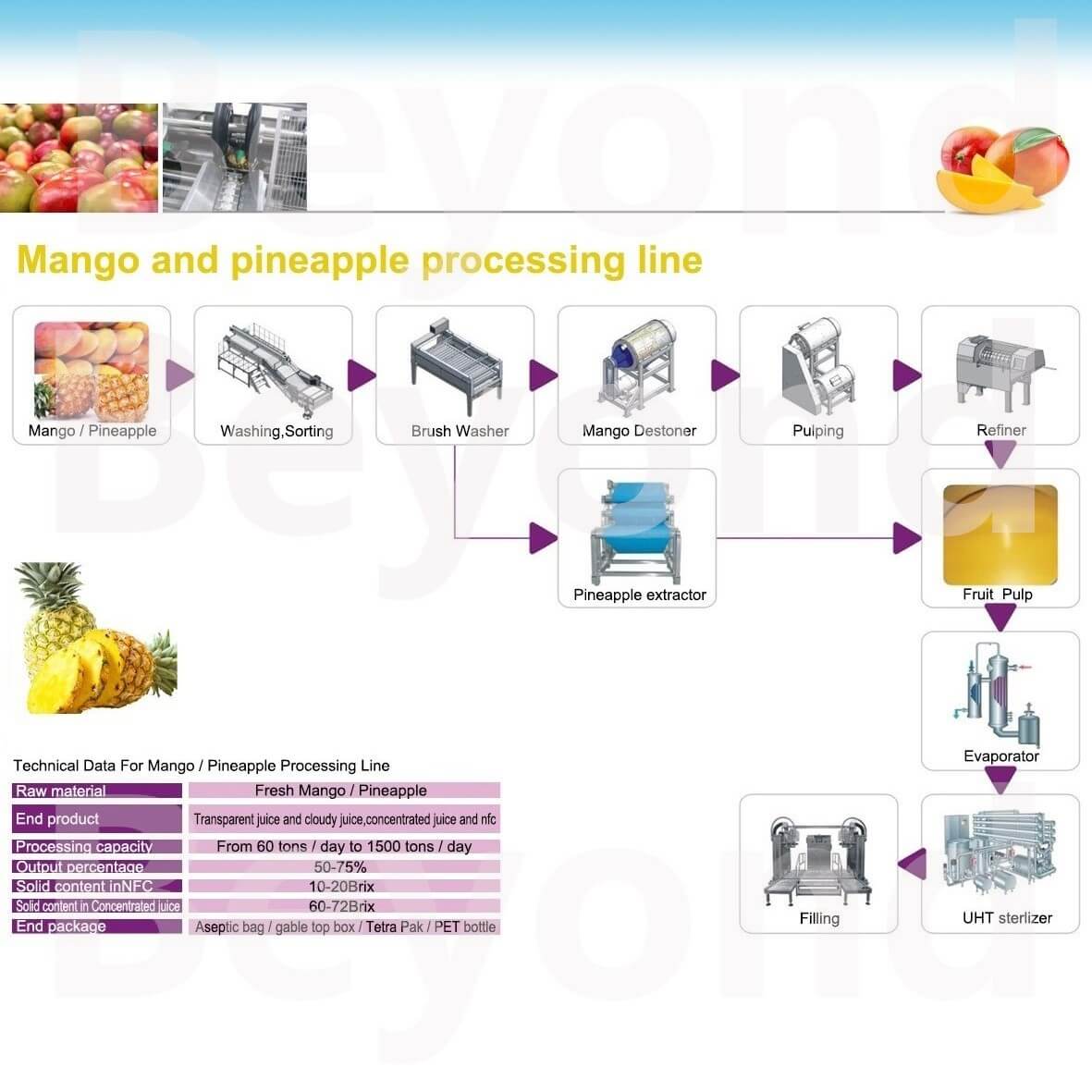

Technical parameters of pineapple processing line:

Raw material: fresh pineapple

Products: Pineapple clear juice or turbid juice, NFC or concentrated juice

Capacity: 60 t / D - 1500 T / D

Juice yield: 50-75%

NFC solid content: 10-20brix

Solid content of concentrated juice: 60 ~ 72brix

Packaging: sterile bag / roof bag / Tetra Pak / PET bottle

You may need a complete solution for food processing. Maybe squeezing fruit into juice is not the end of your equipment.If so, you will be glad to know that beyond can support a variety of food industries and applications. With our extensive mechanical equipment, you can easily complete all steps of food processing.

This is why beyond has become a large juice production line manufacturer, integrated product company and the first choice in the following markets:

Fruit juice and beverages

Fresh cut agricultural products

Nutrition and medicine

No matter how many devices you are looking for, BEYOND's huge product portfolio provides a large number of choices for each food production task. You always leave with a machine suitable for the job at hand.

With the quality and variety of food processing equipment provided by beyond, you can:

Easy access to all devices from a single source

Customize the processing line to meet your needs

Mix and match brands to meet your needs

Easily replace individual components of existing production lines

Respond more flexibly to change

Expand operation scale more smoothly

Customizing a pineapple processing production line involves multiple steps to ensure that the final production line meets your specific needs and quality standards. Here is a detailed customization process:

Customized process for pineapple processing production line

1. Preliminary consultation and requirement collection

•

Goal: Understand your business objectives, production capacity, and expected output.

•

Steps:

•

Requirement assessment: Discuss your production volume, variety of pineapple products (such as sliced, canned, juice, etc.), and any special requirements (such as organic, sugar free, etc.).

•

On site inspection: If possible, visit your factory to evaluate the space, existing equipment, and infrastructure.

2. Design and Planning

•

Goal: Develop a detailed production line design plan.

•

Steps:

•

Process design: Design cleaning, peeling, slicing, sterilization, packaging and other processes according to your needs.

•

Equipment selection: Choose appropriate production equipment, considering the degree of automation, ease of operation, and maintenance costs.

•

Layout design: Reasonably plan the layout of the production line to ensure smooth and efficient operation.

•

Environmental Protection and Safety: Ensure that the production line meets environmental and safety standards, including wastewater treatment and operational safety measures.

3. Equipment procurement and installation

•

Goal: Purchase high-quality equipment and install and debug it.

•

Steps:

Equipment procurement: Purchase the necessary equipment according to the design plan.

•

Installation and debugging: Install equipment on site and conduct debugging to ensure the normal operation of each link.

4. Training and trial operation

•

Goal: Ensure that employees are proficient in operating equipment and the production line is smoothly put into operation.

•

Steps:

•

Employee training: Train operators to ensure they are familiar with the operation and maintenance of equipment.

•

Trial operation: Conduct a production line trial operation to test the performance and coordination of each link.

5. Continuous support and optimization

•

Objective: To provide continuous technical support and optimization suggestions.

•

Steps:

•

Technical support: Provide regular technical support and maintenance services.

•

Performance optimization: Continuously optimize the performance of the production line based on actual operating conditions to improve production efficiency.

•

Troubleshooting: Develop a rapid troubleshooting plan to ensure stable operation of the production line.

•

Key equipment and technology

•

Cleaning equipment: used to remove soil and impurities from the surface of pineapples.

•

Peeling machine: an efficient peeling device that ensures the cleanliness and integrity of pineapple peeling.

•

Slicer: used to cut peeled pineapples into the desired shape and size.

•

Sterilization equipment: using UHT (ultra-high temperature instantaneous sterilization) or pasteurization technology to ensure the safety of the product.

•

Packaging equipment: Automated packaging lines ensure product sealing and hygiene standards.

cost estimation

•

Equipment investment: Depending on the scale and degree of automation of the production line, equipment investment may range from several hundred thousand to several million RMB.

•

Operating costs: including raw materials, energy, labor, and maintenance expenses.

•

Time cycle: From initial consultation to production line launch, it usually takes 6 months to 1 year.

Conclusion

Customizing a pineapple processing production line is a systematic project that requires comprehensive consideration of market demand, production processes, equipment selection, and operating costs.