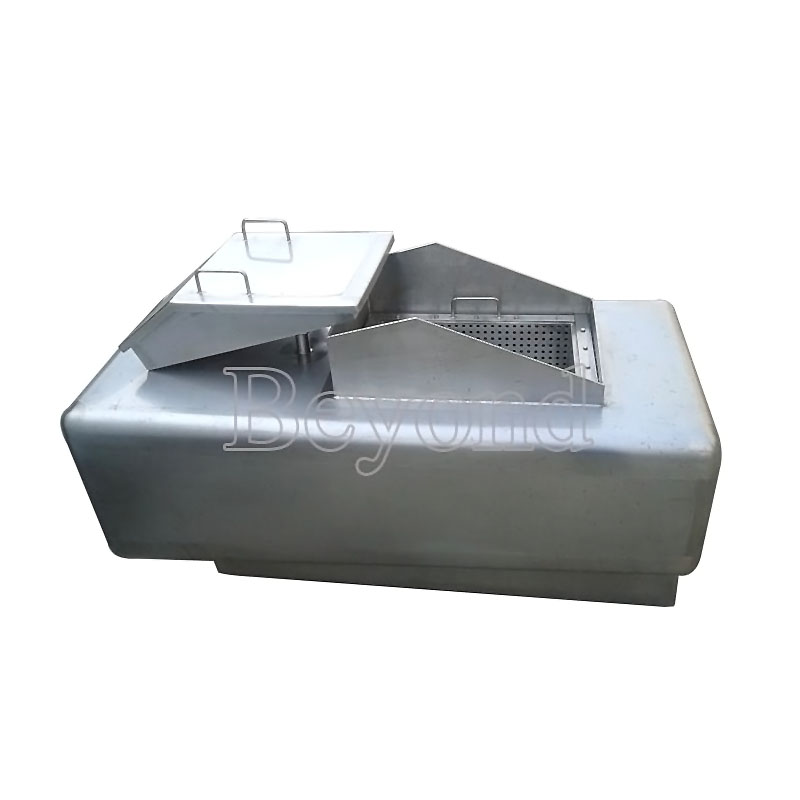

A milk receiving tank is a specialized container used in the dairy industry to collect and store raw milk. It is typically made of stainless steel and designed to meet sanitary standards for milk handling. The tank is usually cylindrical in shape and comes in various sizes, depending on the volume of milk being received.

Milk receiving tanks are commonly found at dairy farms, milk collection centers, or milk processing plants. They serve as the initial point of collection for bulk milk from farmers or milk trucks. The tank is equipped with valves or ports for easy milk intake, which can be connected to a pipeline or hose system for efficient transfer.

The tank is designed to maintain the temperature of the milk during transportation and storage. It may have insulation or cooling systems to prevent spoilage or bacterial growth. Some tanks also incorporate agitators to prevent milk separation and ensure uniformity.

To ensure food safety and quality, milk receiving tanks often have built-in sensors or meters to measure the milk's temperature, acidity, and fat content. This information is essential for quality control and adherence to regulatory standards.

Once the milk is received and measured, it is typically transferred to other processing equipment, such as pasteurizers or storage tanks, for further processing or distribution. The milk receiving tank plays a crucial role in maintaining the integrity and hygiene of the raw milk until it is processed into various dairy products.

Overall, milk receiving tanks provide a hygienic and efficient solution for collecting and storing raw milk, ensuring its safe handling and subsequent processing in the dairy industry.

Type: whole processing Line/turnkey project/fruit and vegetables processing/dairy processing/beverage processing

Voltage: 220v/380vPower(W): 100-200kw

Weight: Different size different weight/customized

Dimension(L*W*H): Different size different dimension/customized

Certification: CE&ISO

Warranty: 12 months/1 year

After-sales Service Provided: Engineers available to service machinery overseas

Main material: SUS304 or SUS316

Control type: automatic, semi-automatic

energy consumption: Low consumption with high efficiency

capacity: 500-10000L/H-customized

installation period: 1-3months

Period time: 30 days-120 days

Cups material: pouches, paper box, glass bottle, pet bottle, glass bottle

Product storage condition: room temperature; low temperature;