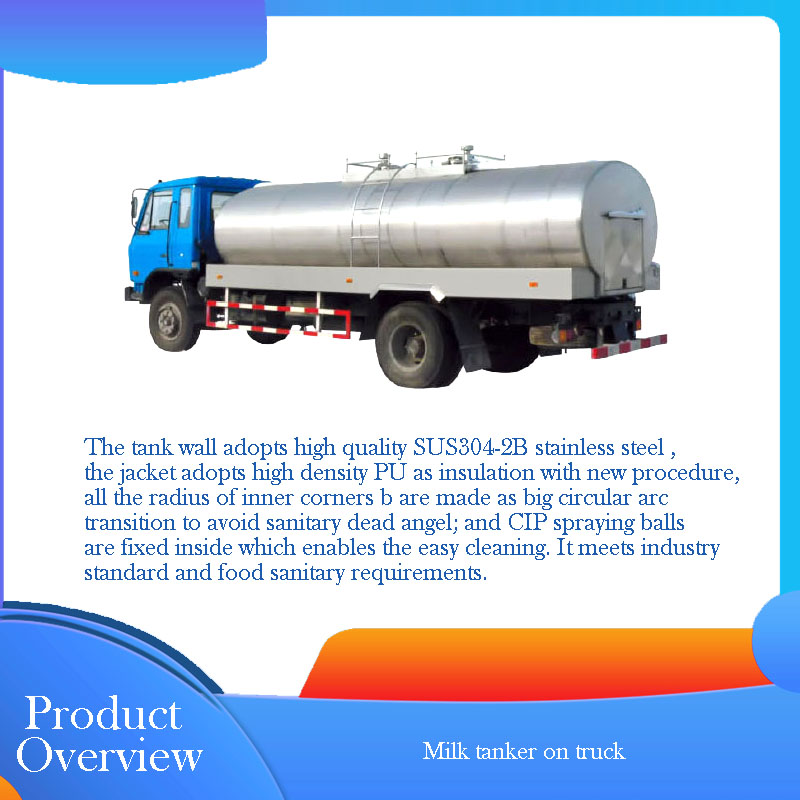

The milk tanker consists of a cylindrical tank mounted on the truck chassis. The tank is usually made of stainless steel or food-grade materials to ensure hygiene and prevent contamination of the milk. It is insulated to maintain the desired temperature of the milk during transportation, especially for dairy products like fresh milk that require refrigeration.

The tanker may have varying capacities, ranging from a few thousand liters to tens of thousands of liters, depending on the size of the truck and the volume of milk being transported. Some tankers may also have multiple compartments to enable separate transport of different types of milk or dairy products.

To facilitate efficient loading and unloading, milk tankers often have specialized features such as top or bottom loading and unloading ports, pumps, and hoses. They may also be equipped with temperature monitoring systems to ensure that the milk remains within the required temperature range throughout the journey.

Milk tankers are an essential part of the dairy industry's supply chain, ensuring the safe and timely delivery of milk and dairy products to meet consumer demand.

| Tank volume | 2000L, 3000L, 4000L, 5000L, 6000L, 8000L, 10000L, 12000L, 15000L, 20000L |

| Temperature | -20ºC~+40ºC, liquid temperature:4+/-1°, temperature difference ≤ 2ºC. |

| Standard configuration |

Quick-opening sealed manhole, breathing valve, CIP cleaning pipes, material inlet (with valve) |

| Material | SUS 304, Food hygiene grade silicone ring for seal |

| Dimension | According to the size of truck chassis provided by customer |

Condition: New

Brand name: Shanghai Beyond;

Type: whole processing Line/turnkey project/fruit and vegetables processing/dairy processing/beverage processing

Voltage: 220v/380v

Power(W): 100-200kw

Weight: Different size different weight/customized

Dimension(L*W*H): Different size different dimension/customized

Certification: CE&ISO

Warranty: 12 months/1 year

After-sales Service Provided: Engineers available to service machinery overseas

Main material: SUS304 or SUS316

Control type: automatic, semi-automatic

energy consumption: Low consumption with high efficiency

capacity: 500-10000L/H-customized

installation period: 1-3months

Period time: 30 days-120 days

Cups material: pouches, paper box, glass bottle, pet bottle, glass bottle

Product storage condition: room temperature; low temperature;