A direct injection sterilizer is a type of equipment used to achieve complete sterilization of various products, including liquids, semi-liquids, and viscous materials. It is commonly used in industries such as food and beverage, pharmaceuticals, and cosmetics.

Unlike pasteurization, which aims to reduce the number of bacteria and pathogens in a product, direct injection sterilization ensures complete elimination of all microorganisms, including bacteria, viruses, and spores. This process helps to extend the shelf life of the product and eliminate the risk of contamination.

The direct injection sterilizer works by injecting steam or hot water directly into the product. The high temperature and pressure achieved effectively kill all microorganisms present in the material. The sterilization cycle consists of heating, holding, and cooling phases to ensure proper treatment of the product.

Direct injection sterilizers often have precise temperature and pressure control systems to ensure the desired sterilization parameters are met. They may also include agitation mechanisms to ensure uniform heat distribution throughout the product.

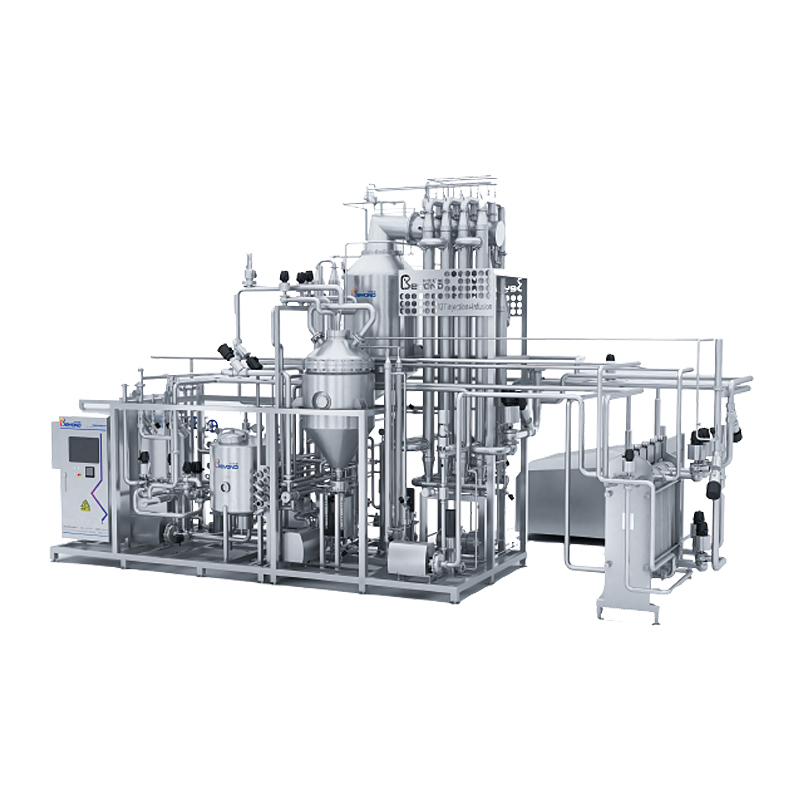

These sterilizers can be designed in different sizes and configurations to accommodate a wide range of production volumes. They are typically made from stainless steel, which is easy to clean and maintain, ensuring hygienic operation and preventing contamination.

Direct injection sterilizers are commonly used for sterilizing liquid products such as juices, sauces, soups, creams, and pharmaceutical formulations. They are highly efficient and offer a reliable method for achieving complete sterilization, meeting the stringent quality and safety requirements of various industries.

The principle of Direct Injection Steam Sterilizer mainly includes the following steps:

1. Steam generation: The steam generator inside the equipment heats water above its boiling point to produce saturated steam. During this process, the pressure and temperature of the steam will be precisely controlled according to the sterilization requirements, typically with sterilization conditions of at least 121 ° C and appropriate positive pressure.

2. Direct steam injection: High temperature and high pressure steam is injected directly into the item to be sterilized through a precisely controlled nozzle, or the item is placed in a sterilization chamber filled with steam. This design ensures that steam can be quickly and evenly distributed, reaching all surfaces and gaps that require sterilization.

3. Heat exchange and sterilization: The injected steam condenses when it comes into contact with the surface of the object to be sterilized, releasing a large amount of latent heat. This can quickly increase the temperature inside the object, effectively killing all types of microorganisms, including bacteria, viruses, and spores.

4. Evacuation and cooling: After the sterilization cycle is completed, steam will be discharged, and the sterilization chamber or container will undergo a cooling process to prepare for subsequent operations or use.

This can be done by introducing sterile air or natural cooling. This technology utilizes the direct action of steam to quickly and effectively complete the sterilization process, and is widely applicable in situations that require efficient sterilization, such as medicine, food processing, and laboratory environments.

Application

Compared to traditional indirect heating methods (such as plate or tubular heat exchanger), direct heating sterilizer rapidly heats the product by directly mixing it with steam, followed by rapid cooling through flash evaporation after the holding period. This significantly reduces the heating time for product , comparable to pasteurization in preserving active nutrients and flavor substances.

The ultra-high temperature used in direct heating greatly enhances sterilization efficiency and significantly extends the shelf life of dairy products. This benefits dairy companies by allowing them to expand their sales radius and increase market share.

Direct Heating Sterilizer is applicable to low-temperature fresh milk, soy milk, heat-sensitive products and certain products that are not compatible with traditional sterilization methods.

Combining direct injection and infusion sterilization methods into one system enables a more flexible production mode, allowing for the switching of different processing techniques according to production needs to meet diverse heat treatment requirements.

Low-temperature products (INF low-temperature fresh milk)

Sterilization at 143-158℃-->0.09s holding-->Flash evaporation-->Homogenization at 65℃-->Discharge at 1-4℃

Ambient temperature products (whipping cream, coconut milk)

Sterilization at 135-142℃-->4/6s holding-->Flash evaporation-->Homogenization at 82℃-->Discharge at 10-25℃

Heat-sensitive products (oat milk)

Sterilization at 115-140℃-->5/10/15/30/60s holding-->Flash evaporation-->Homogenization at 85℃-->Discharge at 60-70℃

The assembly and debugging process of direct injection steam sterilizer is relatively complex, involving professional knowledge and skills, but can be summarized as the following key steps:

1. Preparation before installation: Confirm that the installation environment meets the equipment requirements, including water sources, power sources, drainage, and ventilation conditions. Read and understand the installation manual and safety guidelines provided by the manufacturer.

2. Assemble the main structure: Follow the instructions to assemble the main frame, steam generator, piping system, and control system of the sterilizer. Ensure all connections are tight and well sealed.

3. Electrical and control system connection: Connect power cables, set up control panels and sensors according to the drawings, including temperature, pressure sensors, and valve controllers. Conduct preliminary functional testing to confirm accuracy.

4. Pipeline system inspection and sealing: Conduct a leak test on the entire steam transmission pipeline system to ensure there are no leaks. Use appropriate media (such as water or gas) for pressure testing.

5. Steam generator debugging: Debug the steam generator separately, set the correct temperature and pressure parameters, and verify that it can stably generate saturated steam that meets sterilization requirements.

6. System comprehensive debugging: Integrate all components and conduct complete system operation testing. By simulating the sterilization cycle, check whether each stage is proceeding as expected, monitor temperature and pressure changes, and ensure sterilization effectiveness and equipment safety.

7. Verification and Validation: Conduct physical validation (such as biological indicator testing) and chemical indicator testing according to industry standards or regulatory requirements to ensure the effectiveness of the sterilization process.

8. Operation training: Provide equipment usage, maintenance, and safety training to operators to ensure they can operate the equipment correctly and safely.