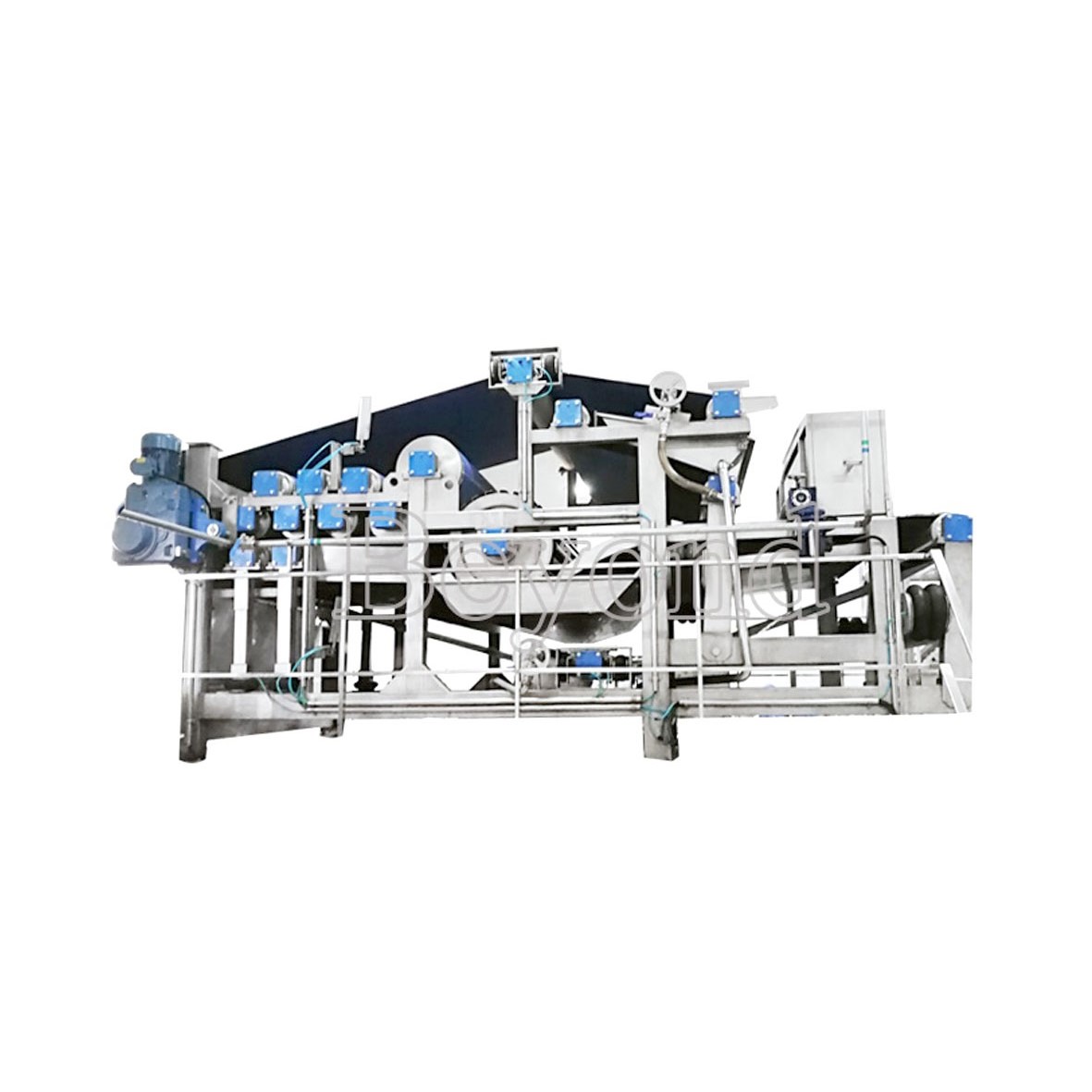

Belt type juice press machine/belt juice extractor

Belt press is a commonly used equipment for extracting fruit and vegetable juice, also known as belt juicer or belt press. It utilizes the synergistic effect of belts and rollers to compress and separate fruits or vegetables, thereby extracting juice.

The belt press has the following main characteristics:

Squeezing and separation: The belt press adjusts the tension and speed of the roller shaft and belt to achieve squeezing and separation of fruits or vegetables. Fruits or vegetables are placed on a belt, and when the belt passes through two rollers, the squeezing effect of the rollers separates the juice from the solid matter.

High efficiency: The belt press adopts continuous operation, which has high production capacity and work efficiency. It can continuously process a large amount of fruits or vegetables, increase the yield of juice, and is suitable for industrial production needs.

Strong adaptability: The belt press is suitable for various types of fruits and vegetables, including citrus fruits, apples, pears, strawberries, carrots, etc. Both soft and hard fruits can adapt to different material characteristics by adjusting the parameters of the belt and roller shaft.

Automation control: Many modern belt presses are equipped with intelligent automation control systems, which can monitor and adjust operating parameters in real-time, improving production stability and consistency.

High extraction rate: The belt press has a high juice extraction rate, which can fully utilize the juice in fruits or vegetables, reduce juice waste, and improve the quality and economic benefits of the juice.

The belt press plays an important role in the production of fruit and vegetable juice, with the characteristics of high efficiency, strong adaptability, and high extraction rate. Whether it is small-scale production or large-scale industrial production, belt press is an ideal equipment worth considering.

Advantages and strong points

The processing capacity is varied from 60 tons/day to 1500 tons/day.

The line Can deal with similar characteristics of fruits.

Using the high efficient of mango destoner to improve the mango output percentage effectively.

Using efficient belt juice extractor to improve the juice efficiency and the output percentage of pineapple.

The production process fully automatic PLC control to save labor and Facilitate production management.

Low-temperature vacuum evaporation ,Maximize reserve the flavor substances and nutrients also save energy.

Tubular UHT sterilizer and Aseptic filling machine, produce high-quality aseptic juice products.

Automatic CIP cleaning ,ensure the entire line equipment of food hygiene and safety requirements

Parameters

|

Raw material |

Fresh Mango / pineapple |

|

End product |

Concentrated juice, clear juice, ,cloudy juice |

|

Processing capacity |

From 60tons/day to 1500 tons/day |

|

Yield |

50-75% |

|

Fruit consistance |

10- 20Brix |

|

Product consistance |

60~72Brix |

|

End package |

Aseptic bag/gable top box/tetra pak/PET bottle |

|

Model

|

Capacity(T/H) |

Power(kw) |

External dimension (mm) |

Belt size(mm) |

|

DYJ-5 |

≤5(T/H)

|

3/21.37 |

4000×2000×2505 |

11800×800 |

|

DYJ -10 |

≤10(T/H) |

4/22.37 |

5000×2500×2505 |

14320×1200 |

|

DYJ -15 |

≤15(T/H) |

4/22.37 |

5400×2880×2505 |

17000×2000 |

|

DYJ -20 |

≤20(T/H) |

5.5/39.87 |

5400×3380×2505 |

17000×2500 |